Rainscreen & cladding

G-Gate Building, Olympia Exhibition Centre

The project

The £1.3 billion transformation of Olympia Exhibition Centre is one of London’s most exciting redevelopments, blending its iconic 140-year-old Victorian halls with modern design to create a dynamic, multi-purpose destination. The new G Gate Building will serve as the primary logistics hub, housing office, exhibition space, and one of the largest theatres built in London since the 1970s. To unite historic and modern elements and reflect its dramatic purpose, the superstructure’s façade features huge triangular fins, echoing pleats of backstage curtains.

Details

Year

2025

Location

London, UK

Building use

Leisure

Building owner

Olympia

Main contractor

Laing O Rourke

Sub-contractors:

Alumet Systems Ltd

Products used

Bespoke solution using RH Rainscreen Horizontal Open State Cavity Barrier

Summary

Specification

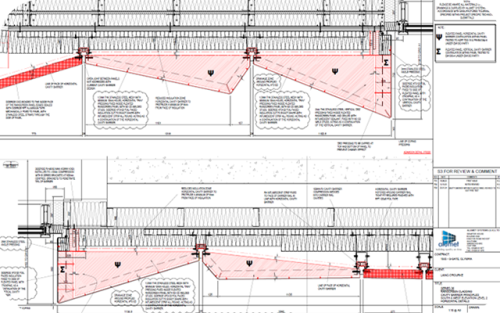

To achieve the requisite fire safety and compliance criteria for this unique architectural element, building envelope contractor Alumet Systems Ltd, approached Siderise for a tested cavity barrier solution that could provide 30 minutes fire resistance without imposing undue load onto the façade system. This collaborative project required experimentation and innovation from Siderise to develop a solid solution for this peculiar detail that would work within the parameters of the existing design and preserve the aesthetic vision.

In addition to the unusual shape, the inner dimensions of the ‘fin’ design aspect were 700mm wide by 1040mm high, presenting a compartmentation challenge due to the unusually large span sizing for a cavity barrier. To address this complexity, the solution was to create a stainless-steel mesh basket that was integrated within the façade panel, and which incorporated an elongated bespoke variant of the RH Rainscreen Horizontal Open State Cavity Barrier installed inside.

Testing

The proposed design required test evidence to demonstrate that it would perform effectively in this uniquely shaped system and therefore would comply with the functional requirements of Building Regulations. We tested the configuration to ASFP TGD 19 Nov 2017 / prEN 1364-6 (using the ISO 834-time temperature curve and other furnace conditions required by BS EN 1363-1: 2020). The testing proved that the performance of the bespoke cavity barrier system achieved a minimum of 30 minutes insulation and integrity.

The test was stopped at 67 minutes with the following results:

- Air gap Thermocouples (Tc) 19 to 28, with gap closed at 0 minutes following the requirements of prEN 1364-6 / ASFP TGD19 Nov 2017, max. temp above gap at start 86°C.

- Insulation criterion maximum temperature rise of 180°C

- Max temp was not reached for duration of test @ 67 minutes.

- Max temp at end of test Tc12 144°C, Tc13 183°C, Tc14 179°C.

- No Integrity failure for the duration of the test.

Fire testing was undertaken at our laboratory in our UKAS accredited Siderise Innovation Centre, which not only made the process more efficient for our client, but also allowed us to provide all the required data and information necessary for the entire project team to be satisfied.

Alumet engaged with Kiwa (IFC) for independent witnessing of the testing and evaluation of the test data which was presented in the final report, thus offering independence and assurance of results and evaluation of the full façade system.

Impact on future projects

The mesh basket concept has since been successfully adapted and implemented on other projects. It has also opened new ways of thinking for the research, development and testing teams at Siderise, and will be an adaptive innovation that evolves and informs future bespoke solutions for ambitious projects with demanding requirements. Chris Mort, our Director of Testing and Project Engineering, explained the significance of the project:

“Our work on the G Gate project and collaboration with Alumet exemplifies exactly what our bespoke solution service is designed to do - create robust passive fire protection systems for projects ready to push the boundaries of what has been done before. This carries huge value to both us in Siderise and the industry as a whole, helping us fuel a virtuous cycle of innovation and improvement as we build a greater collective wisdom through innovation and action in collaboration.

To discuss requirements for your project, speak to our technical team here.

Contact us

Our global teams are ready to provide the support you need