Siderise IC-FS Firestop and IC-CB Cavity Barrier

Factory engineered stone wool passive fire solution for compartmentation in portal frame industrial buildings

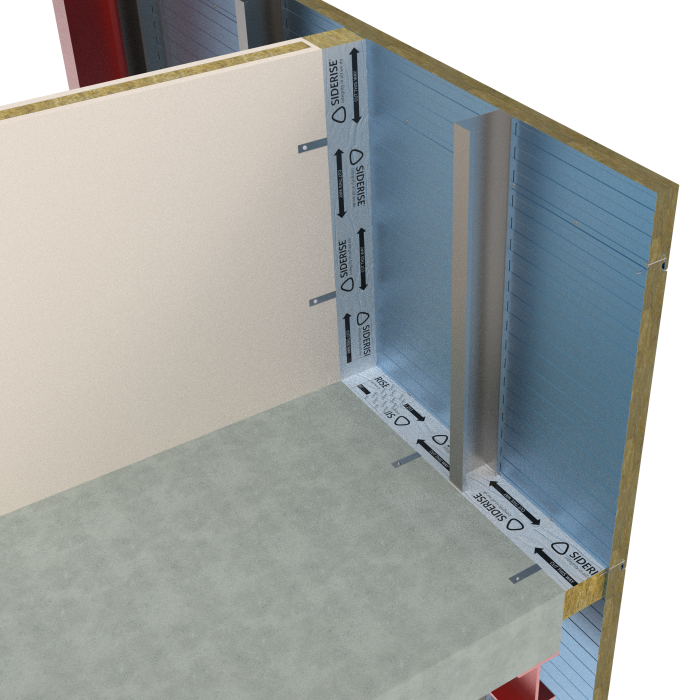

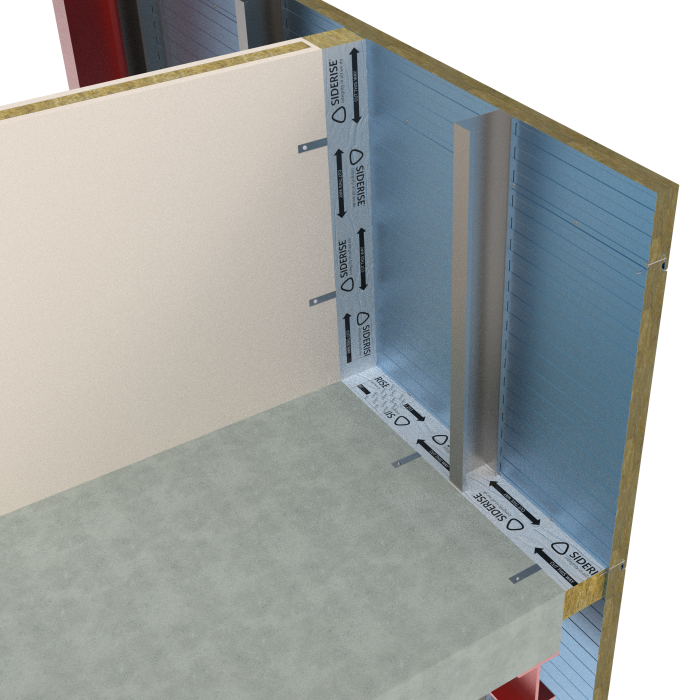

Effective firestopping at junctions where walls and floors meet industrial cladding panel

IC-FS Firestop and IC-CB Cavity Barrier contain fire within designated zones by sealing the gap between compartment floors or walls and the external cladding. The product features a Lamella insulation core comprising pre-compressed durable vertically oriented stone wool fibres laterally compressed under factory-controlled conditions. This pre-compression, which is held in place by aluminium foil facings, allowing IC-FS Firestop and IC-CB Cavity Barrier to accommodate building movement and façade deflection, providing a tight seal for the lifetime of the building.

IC-FS and IC-CB Cavity Barrier have been tested to BS EN 1366-4: 2006+A1: 2010 to determine performance when used in both a vertical and horizontal orientation between two fixed elements.

IC-FS60 and IC-FS120 are certified to deliver 1 and 2 hours fire resistance, respectively.

IC-CB30 is certified to deliver 30 minutes of fire resistance.

To confirm in-application durability and robustness in its ability to maintain its form and performance when exposed to specific use conditions, IC-FS Firestop and IC-CB Cavity Barrier have been subjected to EOTA Technical Report 024 ‘Type X’ accelerated age testing - the harshest category, which replicates exposure to rain, UV, high temperatures, and frost and thaw cycles.

Siderise IC-FS Firestop and IC-CB Cavity Barrier offers a solution for firestopping in industrial portal framing buildings as per the requirement in section 7.3 of Approved Document B which mandates that firestopping is provided at compartment walls or close to a site boundary to prevent fire spread to adjacent properties.

The primary function of IC-FS and IC-CB is to provide compartmentation from the internal compartment floor or wall of a portal frame building to the outer façade. IC-FS and IC-CB has been tested in both horizontal and vertical orientations.

Siderise IC-FS and IC-CB lamella construction also provides the ability to accommodate movement for the expected service lifespan of the product of 60 years. Siderise’s Lamella features a special formulation of stone wool insulation with vertically oriented fibres, instead of a horizontal fibre structure.

These vertical fibres are laterally compressed under quality-controlled factory conditions to assist with uniform density and remove any gaps between the adjoining cut sections, which may otherwise result in weakness. This ‘pre- compression’ is held in place by carrier facings (typically foil), which are heat applied to the cut faces of the fibres.

The result of these pre-compressed vertical stone wool fibres that sit perpendicular to the substrate in application is manifold in terms of performance characteristics. This includes a durable and resilient one-piece, dry-fit fire barrier solution; a tight fit; the ability to withstand building and façade movement; mitigating the risk of cladding panels bulging after panel installation; eliminating the need for a secondary wet seal; and facilitating a quick and simple installation process with straightforward compression in voids alongside our friction fit product ranges

Siderise IC-FS and IC-CB are manufactured using a method that provides resilient lateral compression. This facilitates installation, ensuring the requisite tight fit and enhancing the fire integrity of the product.

Throughout the range, the materials comprise a one-piece product with a pre-compressed non-combustible stone wool core. The products also have integral aluminium foil facings to provide an overall Class A1 rating (to BS EN 13501- 1:2018 “Fire classification of construction products and building elements.”).

IC-FS is offered with a 1- or 2-hour fire resistance, with the IC-CB offering 30-minute fire resistance, and can accommodate void widths up to 400mm. In addition to providing an effective seal against the passage of fire, the products are also acoustically absorptive.

Standard Systems

The materials can be either supplied as pre-cut units to suit a specified void size or in sheet form for cutting on-site. Standard sheet products are supplied 1200 x 1200 mm which may prove beneficial when the actual void size is not known or where it varies significantly. Please note that when ordered in sheet form, the requisite quantity of fixing brackets needs to be purchased separately.

Pre-cut strips are available in 1mm increments of width to suit the cavity size to provide a tight compressive fit within the void - Please see Table 2 regarding fit type. Each pre-cut IC-FS and IC-CB unit is supplied with appropriate fixing brackets as part of the system.

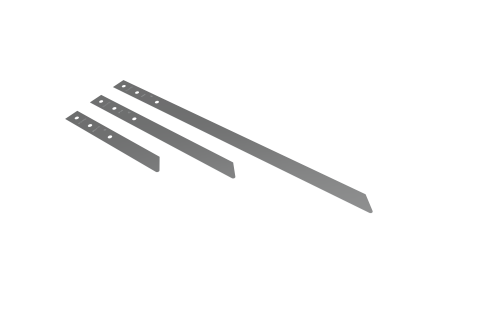

The standard fixing brackets are supplied in galvanized mild steel in a flat form for folding on-site. Brackets are also available in stainless steel. All hole positions are to be drilled to suit the varying site conditions. Different size brackets are available according to the cavity size – see Table 1. All fixing brackets are to be mechanically secured to the substructure with suitable non-combustible fixings.

Reaction to fire

Siderise IC-FS Firestops and IC-CB Cavity Barriers are classified as A1 to BS EN 13501-1:2018

Resistance to fire

Siderise IC-FS Firestops and IC-CB Cavity Barriers have been proven to maintain their integrity (E) and insulation (I) requirements when tested, in vertical and horizontal applications to BS EN 1366-4:2006+A1:2010 “Fire resistance tests for service installations - Linear joint seal”.

For any voids not covered by Table 1, please contact [email protected] for advice on these options.

Third-party Certification

IFC certification (IFCC 2501) is available based on proven fire performance for horizontal and vertical applications to BS EN 1366-4:2006+A1:2010 (Table 1).

For further details on all Third-party Certification, the certificates can be downloaded from our online technical resources or from the certification body.

Table 1: Fire Resistance to BS EN 1366-4:2006+A1:2010 (Vertical & Horizontal Orientation)

| Product Ref | Void Width (mm) | Thickness (mm) | Compression (min.) | Integrity (Mins) | Insulation (mins) | Product Length (mm) | Bracket Requirement | Third-party Certification |

|---|---|---|---|---|---|---|---|---|

|

IC-CB30 |

20 - 50 |

75 |

+10% |

90 |

30 |

1200 |

None. |

IFCC 2501 |

|

51 - 150 |

75 |

+10% |

90 |

30 |

1200 |

2no.B65/110 600mm centres |

IFCC 2501 |

|

|

151 - 250 |

75 |

+10% |

90 |

30 |

1200 |

2no.B195 600mm centres |

IFCC 2501 |

|

|

IC-CB30X |

251 - 400 |

90 |

+10% |

90 |

30 |

1200 |

2no.B355 600mm centres |

IFCC 2501 |

|

IC-FS60 |

20 - 50 |

100 |

+10% |

90 |

60 |

1200 |

None. |

IFCC 2501 |

|

51 - 150 |

100 |

+10% |

90 |

60 |

1200 |

2no.B65/110 600mm centres |

IFCC 2501 |

|

|

151 - 250 |

100 |

+10% |

90 |

60 |

1200 |

2no.B195 600mm centres |

IFCC 2501 |

|

|

IC-FS60X |

251 - 400 |

120 |

+10% |

90 |

60 |

1200 |

2no.B355 600mm centres |

IFCC 2501 |

|

IC-FS120 |

20 - 50 |

120 |

+10% |

120 |

120 |

1200 |

None. |

IFCC 2501 |

|

51 - 150 |

120 |

+10% |

120 |

120 |

1200 |

2no.B65/110 600mm centres |

IFCC 2501 |

|

|

151 - 250 |

120 |

+10% |

120 |

120 |

1200 |

2no.B195 600mm centres |

IFCC 2501 |

|

|

IC-FS120X |

251 - 400 |

150 |

+10% |

120 |

120 |

1200 |

2no.B355 600mm centres |

IFCC 2501 |

Whilst the IC-FS and IC-CB range has been tested in general accordance with BS EN 1366-4:2006+A1:2010 in narrow void widths 20-50mm without mechanical fixings and brackets, we note that some supervising authorities may require a form of mechanical fixing. We recommend engaging with the project supervising authorities prior to installation to ensure all their requirements are met.

- For vertical firestop applications to the end of a flexible wall (e.g. stud partitions), please consult [email protected] for advice on appropriate product selection and application.

- All fixing brackets are to be mechanically fixed to the structure. Please see the installation instructions.

- Façade deflection should be taken into consideration with respect to installation compression.

The IC-FS and IC-CB range of barriers are also acoustically absorptive. Furthermore, the foil facings and the additional sealing of joints with Siderise foil tape all serve to provide improved airtightness.

Table 2 confirms the laboratory tested values for Weighted Sound Reduction Index (dB Rw) in accordance with BS EN ISO 10140-2:2021; Acoustics-Laboratory measurement of sound insulation of building elements, Part 2: Measurement of airborne sound insulation.

Table 2: Acoustic Performance - Weighted Sound Reduction Index

| Product Type | Thickness (mm) | Rw (dB) | C:Ctr |

|---|---|---|---|

|

IC-CB30 |

75 |

21 |

(-1;-2) |

|

IC-CB30X |

90 |

21 |

(-1;-2) |

|

IC-FS60 |

100 |

21 |

(-1;-2) |

|

IC-FS60X |

120 |

23 |

(-1;-3) |

|

IC-FS120 |

120 |

23 |

(-1;-3) |

|

IC-FS120X |

150 |

23 |

(-1;-3) |

Rw is the weighted sound reduction index. It is a laboratory measured value to identify the airborne sound insulation performance of a building element. It is used for internal or external walls, ceilings/floors, windows, doors, or any separating element. The higher the Rw value, the better that element performs in reducing sound transmission. Please note that the values presented in the above table refer to the standalone performance of the Siderise products only.

Siderise IC-FS and IC-CB – Industrial Cladding Firestop and Cavity Barrier

Table 3: Product Properties

| Properties | Value |

|---|---|

| Form Supplied |

Sheets : 1200mm x 1200mm; Thickness is denoted by the rating Pre-cut strips: 1200mm x (void width + compression) x thickness, please see table 1 |

| Colour |

Solid, green-brown exposed edges with silver aluminium top and bottom facings |

| Finish |

Aluminium Foil |

| Void Width |

20mm to 400mm (see Table 1) |

| Fungi Resistance |

When tested to ASTM C1338-19 no fungal growth was observed after 28 days |

| Water Vapour Absorption |

<5% by weight to ASTM C1104-19 (with foil facing removed). This meets the standard specification for ‘Mineral Fibre Blanket Thermal Insulation for Light Frame Construction and Manufactured Housing’ ASTM C C665-17, clause 7.5 |

| Reaction to fire |

Class 'A1' to BS EN 13501-1:2018 |

| Resistance to fire |

30, 60, or 120 minutes (see tables 1) |

Recyclability

The stone wool core is recyclable.

60 Year Design life

To confirm long-term durability, IC-FS and IC-CB have been put through EOTA TR 024 ‘Type X’ accelerated age testing. This is the harshest category which replicates exposure to rain, UV, high temperatures, and frost and thaw cycles.

When correctly installed in recommended applications, IC-FS Firestops and IC-CB Cavity Barriers have an expected service lifespan of 60 years.

The following information is available upon request or via download from the website:

- Third-Party Certification

- Material Data Sheet

- Standard Details

- Installation Instructions

For technical advice or support please contact: [email protected]

For Installation Training or Site Inspections please contact: [email protected]

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

FAQs

Find answers to some of the most frequently asked questions

Yes, our site services engineers combine classroom learning with toolbox training and includes mock-up benchmark installations, free-of-charge.

Our void sizes vary depending on the product, required fire resistance, test standard and installation compression. You can view the available void sizes on each product’s technical data sheet.

Siderise developed a unique automated ‘high speed lamella’ manufacturing process in the 1990s to provide a fire resistant stone wool core that could also withstand building movement for reliable form and fit. Learn more about our Lamella technology.

Augmented Reality

Point your camera at the QR code. Tap the banner that appears on your screen.