Siderise OSCI Open State Cassette Insert

Stone wool inserts to reduce the depths of cladding cassettes and simplify detailing

Consistent cavities

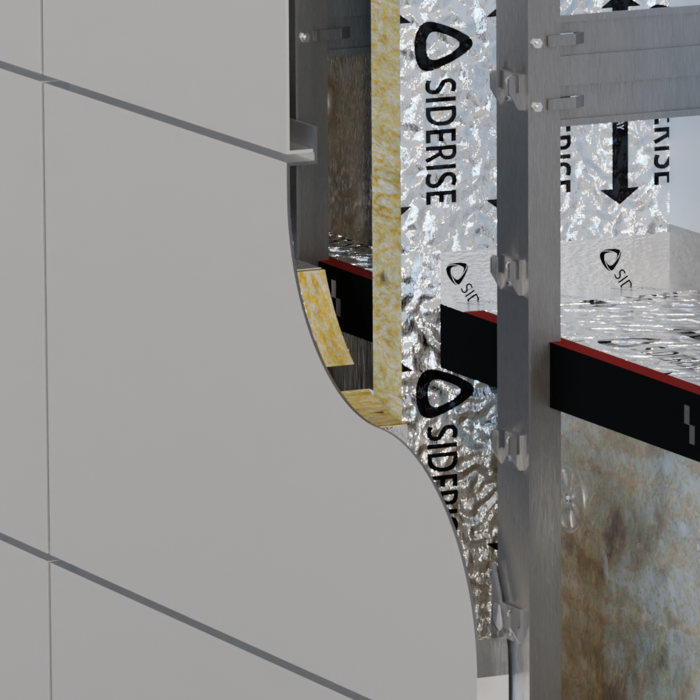

OSCI Open State Cassette Insert is a small block of A2-s1,d0 rated stone wool with foil-facings and an integral self-adhesive strip. This allows it to be directly applied to the internal surface of cassette panels to create a flat surface opposite Siderise RH or RV Cavity Barriers — simplifying their detailing and installation and ensuring that the ventilation air gap is dimensioned within permissible limits.

OSCI Open State Cassette Insert can be used in combination with either RH Horizontal Cavity Barrier, CH Horizontal Cavity Barrier or RV Vertical Cavity Barriers.

OSCI Open State Cassette Insert is available in a range of thicknesses and widths to accommodate most types of cassette panel designs

The product has been classified A2-s1,d0 in accordance with EN 13501-1 for Reaction to Fire

To confirm long-term durability, OSCI Cassette Inserts in combination with Siderise Cavity Barriers for Rainscreen & Cladding have been put through EOTA TR 024 ‘Type X’ accelerated age testing the harshest category, which replicates exposure to rain, UV, high temperatures, and frost and thaw cycles.

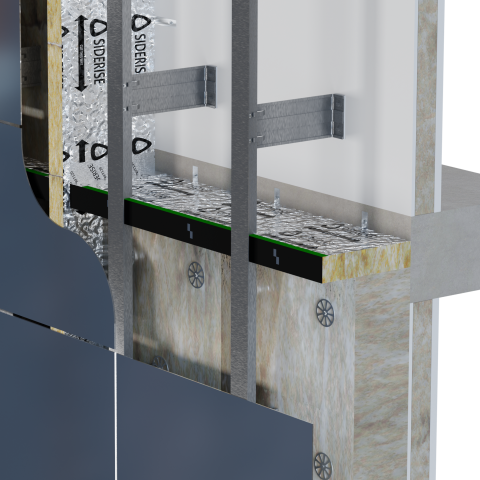

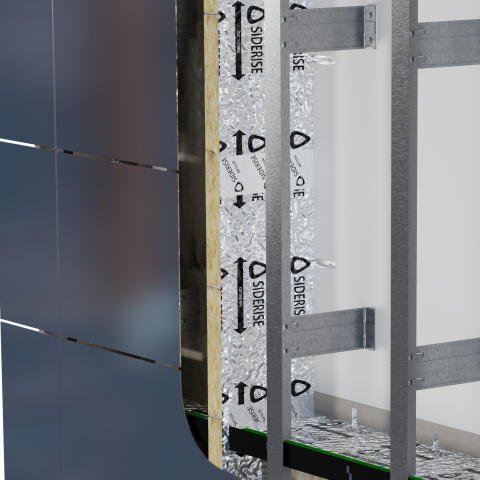

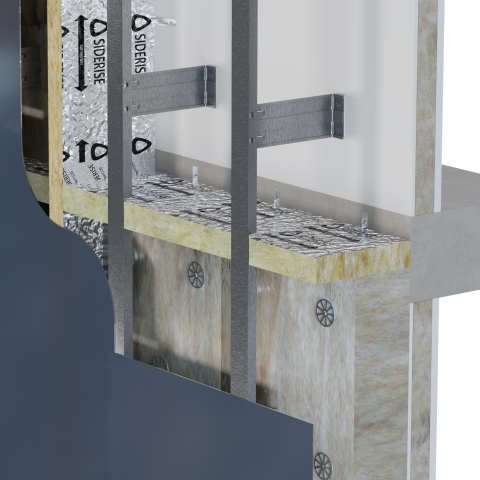

Siderise Open State Cassette Inserts (OSCI) are designed for use in Cassette Panel Cladding Systems.

OSCI can be used both horizontally and vertically as part of a rainscreen cladding system. They are applied directly to the internal surface of the cassette panel to simplify the detailing and installation of adjacent cavity barriers and/or to ensure that the ventilation air gap is dimensioned within permissible limits.

OSCI are positioned parallel and aligned centrally to Siderise 'RH' or 'RV' Cavity Barriers, taking into account the specification of the cladding system assembly. Typically, this requires consideration of the specification and configuration of the cladding panels, the positioning of the support rails or similar steelwork, and/or hook-on or bracket arrangements for panel support.

Siderise OSCI products are manufactured from non-combustible stone wool (Class A1 to BS EN 13501-1:2018 “Fire classification of construction products and building elements – Classification using data from reaction to fire tests”) with a nominal density of 110 kg/m³. The product incorporates a foil facing on two sides, with one side featuring a modified acrylic pressure-sensitive adhesive protected by a strippable film.

OSCI are available in a range of sizes and are selected according to the type and size of the corresponding Siderise Cavity Barrier specification on a project basis. Please refer to Table 1.

Siderise OSCI have demonstrated fire performance via a variety of cassette panel cladding system tests to BS 8414 and NFPA 285. For information regarding performance and assembly details in system tests please see our System Test page.

Standard available Siderise OSCI as per Table 2 are classified 'A2-s1, d0' to BS EN 13501-1:2018 for Reaction to Fire.

Please Note:

It is the responsibility of the system designer, supplier and/or contractor to ensure that the final system and all associated components meet all functional and regulatory requirements. This includes the suitability and inclusion of OSCI.

Please contact Technical Services for further advice - [email protected]

Thermal Conductivity is 0.043 W/m.K.

Siderise OSCI products are manufactured from high-density non-combustible stone wool (Class A1) with a foil facing on two sides. One side has an additional modified acrylic pressure-sensitive adhesive with a strippable film.

Once in position, Siderise Aluminium Jointing Tape (RFT120/45) must be applied to cover the stone wool faces and overlap onto the rear of the cladding panel and OSCI foil facing. Please see installation instructions for further details.

Whilst OSCI's have been successfully tested as components within full-scale system fire tests without mechanical fixing (i.e. via adhesive fixing only), it is assistive where possible to place the OSCI within cassette panel returns.

Please note: We can confirm that we can support the use of the OSCI without mechanical fixings when bonded to an aluminium substrate in line with our installation instructions. However, we note that it is the preference of some authorities, such as NHBC, to use additional mechanical retention, which we have no objection to in principle. Examples of how mechanical retention might be added are included in the OSCI Installation Instructions. Where NHBC has an involvement in the project, we suggest engaging with them to agree any such provision. A similar engagement should be made with any other Supervisory Authorities to verify whether they have any such requirements.

Additional Installation Instructions

Application can be either in factory conditions prior to delivery, or on-site. In both instances, the product must be kept dry and installed in dry conditions. The surface of the panel should be clean and free from contamination. It should be degreased where necessary and fully dry.

Positioning

- Careful measurement and marking of the appropriate position of the OSCI onto the panel is essential.

- Once the adhesive backing is removed and the OSCI is fixed it will be very difficult to remove without damaging the OSCI and requiring replacement.

- The OSCI should be positioned parallel and central to the corresponding Siderise 'RH' or 'RV' Cavity Barrier.

- Having placed the OSCI onto the back of the panel, it should be offered up to ensure correct alignment with the Siderise 'RH' or 'RV' Cavity Barrier.

- If alignment is not achieved, then the OSCI must be repositioned accordingly. If during repositioning, damage to the adhesive tape occurs that could compromise the bond between the OSCI and panel, it is recommended that the poorly aligned OSCI is discarded and a new piece fitted in the correct position.

Profiled cassette panels will sometimes feature panel 'stiffeners', often in the form of a hollow top hat section bonded to the rear of the cassette panel. The profiles are usually applied during the fabrication of the panels prior to the application of the OSCI, meaning they intersect the OSCI and provide a clear route for fire to bypass the OSCI and cavity barrier provision. The extent of the stiffener usually means there is no way to infill the void within the stiffener after it has been applied to the panel.

These stiffeners are not always identified on project drawings and so we would suggest seeking advice from the panel manufacturer at the earliest opportunity to clarify whether they intend to apply any such stiffeners to the panels and to consider how they can be addressed at the production stage. Please contact [email protected] with details of any stiffeners present in your proposed design and we will be happy to advise on the most appropriate approach to address them.

Fitting

- Check the surface of the panel is clean and free from contamination. Degrease where necessary and ensure the surface is fully dry.

- Check the adhesion of the OSCI to the panel surface before offering it up to the assembly.

- Cut the OSCI to the appropriate length and insert it onto the surface of the panel by removing the self-adhesive strip and pressing firmly down onto the surface.

- Apply uniform pressure across the OSCI to ensure it is firmly fixed in place, taking care to position the OSCI under the top lip of any returns on the cassette panel to make sure that the panel is filled and to aid retention.

- Siderise Aluminium Jointing Tape (RFT120/45) must be applied to cover the stone wool faces and overlap onto the rear of the cladding panel and OSCI foil facing to ensure a weather-tight seal.

Joints

- Maximum lengths should be used wherever possible to minimise the number of joints.

- The OSCI can be jointed, the minimum length that can be used is 200mm.

- The joints between the individual lengths of OSCI should be tightly butted and taped with Siderise foil tape RFT 120/45.

Adhesion

- Whilst large-scale testing of OSCI has been carried out with ACM panels, the surface of ACM facade panels and therefore suitability for adhesion may vary.

- All panels must be checked for adhesion to the OSCI and advice sought from Siderise should doubts arise about OSCI/Panel compatibility.

Please see separate Installation Instructions for further information.

Siderise offers Site Services support whereby we attend the site to assist in the preparation of a mock-up or benchmark area to facilitate a successful installation.

Please contact [email protected] for further information.

Table 1: OSCI selection by adjacent Cavity Barrier Thickness

| Siderise Cavity Barrier Type | Cavity Barrier Orientation | Cavity Barrier Thickness (mm) | OSCI Width (mm) |

|---|---|---|---|

|

RH25-90/30 |

Horizontal |

75 |

100 |

|

RH25-60/60 |

Horizontal |

90 |

115 |

|

RH25-90/60 |

Horizontal |

90 |

115 |

|

RH25-120/60 |

Horizontal |

120 |

145 |

|

RH25-120/90 |

Horizontal |

120 |

145 |

|

RH25-120/120 |

Horizontal |

120 |

145 |

|

RH50-30/30 |

Horizontal |

75 |

100 |

|

RH50-60/60 |

Horizontal |

90 |

115 |

|

RV-90/30 |

Vertical |

75 |

100 |

|

RV-90/30X |

Vertical |

90 |

115 |

|

RV-90/60 |

Vertical |

100 |

125 |

|

RV-90/60X |

Vertical |

120 |

145 |

|

RV-120/120 |

Vertical |

120 |

145 |

|

RV-120/120X |

Vertical |

150 |

175 |

Table 1 above provides the OSCI width which is determined by the fire rating of the Siderise Cavity Barrier in use on the project.

Siderise OSCI should not be used in conjunction with cavity barriers from another manufacturer or type.

Table 2: Product Codes and Dimensions

| Product Type | Width (mm) | Length (mm) | Depth (mm) |

|---|---|---|---|

|

OSCI/1220-100-40 |

100 |

1220 |

40 |

|

OSCI/1220-100-50 |

100 |

1220 |

50 |

|

OSCI/1220-100-60 |

100 |

1220 |

60 |

|

OSCI/1220-115-40 |

115 |

1220 |

40 |

|

OSCI/1220-115-50 |

115 |

1220 |

50 |

|

OSCI/1220-115-60 |

115 |

1220 |

60 |

|

OSCI/1220-125-40 |

125 |

1220 |

40 |

|

OSCI/1220-125-50 |

125 |

1220 |

50 |

|

OSCI/1220-125-60 |

125 |

1220 |

60 |

|

OSCI/1220-145-40 |

145 |

1220 |

40 |

|

OSCI/1220-145-50 |

145 |

1220 |

50 |

|

OSCI/1220-145-60 |

145 |

1220 |

60 |

|

OSCI/1220-175-40 |

175 |

1220 |

40 |

|

OSCI/1220-175-50 |

175 |

1220 |

50 |

|

OSCI/1220-175-60 |

175 |

1220 |

60 |

For required OSCI width please see Table 1.

The depth of the OSCI can be variable with a minimum depth of 21mm. The sizes quoted in Table 2 would be considered standard.

Other OSCI depths are available, please contact [email protected] for further information.

Siderise OSCI should not be used in conjunction with cavity barriers from another manufacturer or type.

Recyclability

The stone wool core is recyclable.

60 Year Design life

To confirm long-term durability, OSCI Cassette Inserts in combination with Siderise Cavity Barriers for Rainscreen & Cladding have been put through EOTA TR 024 ‘Type X’ accelerated age testing. This is the harshest category which replicates exposure to rain, UV, high temperatures, and frost and thaw cycles.

When correctly installed in recommended applications in combination with Siderise Cavity Barriers for Rainscreen & Cladding, OSCI Cassette Inserts have an expected service lifespan of 60 years.

The following information is available upon request:

- Material Data Sheet

- Installation Instructions

- Material Handling

- Standard Details

- NBS Specification Clauses

For technical advice, support, or classification reports, please contact the Technical Services Team: [email protected]

For Site advice, installation training and inspection, please contact the Site Services Team: [email protected]

For technical advice or support in the Middle East, India or Asia Pacific contact: [email protected]

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

Products

Related products

Siderise products developed to meet the unique demands of cladding façades

FAQs

Get quick answers to common queries or contact our team for more advice. Your questions answered.

Yes, our site services engineers combine classroom learning with toolbox training and includes mock-up benchmark installations, free-of-charge.

Yes, brackets are available in two forms: galvanised steel brackets (G) and denotes stainless steel OSCI Open State Cassette Insert has been included in large-scale fire tests of multiple cladding systems, such as BS 8414 and NFPA 285. Please see our database of large scale testing for more information

One side of the product features a pressure-sensitive adhesive strip. This allows it to be adhered to the back of the cassette, parallel to the corresponding Siderise Cavity Barrier. On some projects, it may be necessary to use additional mechanical retention. Please see our installation documents for more detail

Case Studies

Related projects

Siderise is a market leader in the design and development of specialist passive fire.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Augmented Reality

Point your camera at the QR code. Tap the banner that appears on your screen.