Why are cavity fire barriers key to rainscreen façade performance?

Rainscreen façade systems are a popular choice for building exteriors in many parts of the world, thanks to their energy efficiency benefits and wide aesthetic possibilities. However, the air gap between the inner and outer finishes of these ‘double wall’ constructions can present a very serious fire risk if not carefully considered, especially in densely populated cities where high-rise residential buildings are becoming commonplace.

What is a rainscreen façade system?

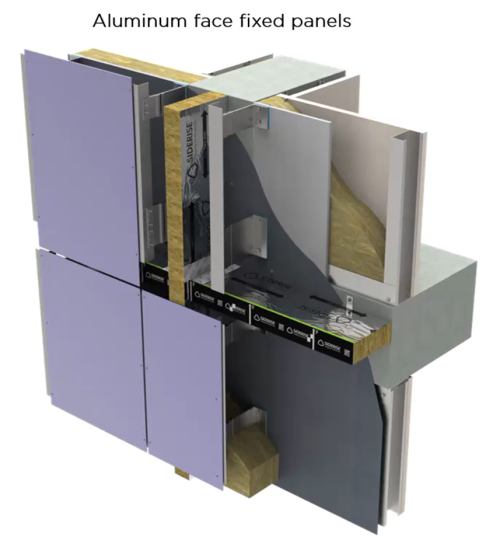

Rainscreen systems typically consist of:

a backing wall or an inner concrete structural element

an insulation layer

waterproofing layers

brackets

the external cladding finish, e.g. aluminium cassette panels, brick slips.

Separating the inner wall from the outer skin is an air gap. Also referred to as a cavity, this space allows any moisture that enters the façade system due to rainfall or humidity to (depending on the system design, i.e. ventilated and drained or pressure equalised) either effectively drain or vent away, or limit water penetration, preventing condensation, corrosion and mould growth. This is why rainscreen façades are also often referred to as ventilated façades. Non-ventilated systems may be preferred where there is a low risk of water ingress, for example in dry climate zones.

Additionally, due to the air pressure differential between the bottom and top of the cavity, this gap allows a continuous cycle of air to flow through the cavity from top to bottom. This helps to cool down the exterior of the building, supporting comfortable temperatures indoors without over-reliance on potentially costly mechanical air conditioning — making them a sensible choice for projects aiming for lower operational costs and higher sustainability credentials.

How can we prevent fire spreading through rainscreen systems?

In the event of a fire entering the external wall construction, this cavity can pose a real challenge to the building’s fire safety as it draws the heat, smoke and flames up the building, affecting multiple floors and putting many lives at risk. Even the smallest fire within the cavity can quickly become ferocious as the confined space means any radiant heat is trapped and can only travel upwards, creating a hotter fire that can easily spread.

To prevent this, it is crucial that the cavity within a rainscreen system is closed off using cavity barriers— blocks of fire-resistant material which seal the cavity in strategic locations, such as at junctions between walls and floors and around windows and doors, to subdivide the cavity into smaller voids creating compartments that contain the fire into an area of manageable risk until it can be fully extinguished. This prevents extensive fire spread, allowing occupants enough time to escape, fire and rescues services to perform their operations, and limiting property and asset damage.

What are the rainscreen cavity fire barrier options?

Standard cavity fire barriers are ‘full fill’ or ‘closed state’ products, meaning they are fitted directly between the internal and external layers to completely seal the cavity. This makes them ideal for vertical applications as they can help maintain the air pressure within compartments, preventing the fire from spreading horizontally around the building.

However, full-fill cavity fire barriers are not suited to horizontal applications in rainscreen façades as this would prevent the system from effectively ventilating or draining away water, resulting in condensation forming within the cavity. This would lead to moisture build-up on the cavity barrier and damp within the building envelope.

To resolve this issue, ‘open state’ cavity barriers (OSCBs) were developed. These include an integral intumescent material that rapidly expands in reaction to high heat (around 130°C). This allows them to be fixed to the internal wall, leaving the ventilation gap open to allow for free flowing movement of air and moisture drainage and evaporation day-to-day (sometimes referred to as the ‘cold state’). However, in the event of a fire, the intumescent expands in a matter of seconds until the void is fully closed and a robust fire seal is formed.

How do I choose the right cavity fire barrier for rainscreen?

Both testing and real-world fires demonstrate that cavity barriers can make a significant contribution to the overall passive fire safety of a building, whilst selecting cladding and cavity barrier systems that are appropriate for the climate conditions can help avert moisture related issues.

To specify them correctly, it is important to understand what fire test standards to look out for. Standard full-fill cavity barriers can be tested to EN 1366-4 Fire resistance tests for service installations - Part 4: Linear joint seals. This standard determines the fire resistance of linear joint seals. It tests both horizontal and vertical applications and allows some movement in one direction before the test starts.

The Association for Specialist Fire Protection (ASFP) Technical Guidance Document TGD 193 and the recently published European standard EN 1364-6: 2025 standard both outline test configurations and failure criteria for the testing of OSCBs. These tests are based on the existing EN 1366-4 linear joint seal test (using the principles of EN 1363-1) with some modifications, including allowing five minutes for the intumescent to close the gap.

Whilst these tests can determine standalone cavity barrier performance and therefore general suitability for the purpose it is marketed for, it is only through large-scale testing that we can fully understand how complete assemblies perform in their intended application and how they might perform in a real-life fire scenario. Large-scale testing examines all the system components together, providing data on how the different products interact, along with the impact of details such as joints, gaps, and penetrations on the overall fire performance. Therefore, data from large-scale systems tests such as BS 8414-1 &2 and NFPA 285 that evaluate the performance of a complete façade assembly can be invaluable when considering cavity barriers.

It is important to note that, even with the inclusion of cavity fire barriers, rainscreen systems can fail if the external cladding allows the fire to spread up the outside of the building causing the panels to move, break down or come away. Any malfunction with the cladding would likely leave a path for the flames to spread up and over the cavity barrier and into the cavity. Therefore, it is vital to always refer to the latest specialist advice for façade design and specification, and to ensure high quality workmanship at every stage.

What are the Siderise solutions for rainscreen applications?

External cladding façade systems bring both a wealth of creative potential and clear thermal efficiency benefits to all kinds of buildings. Ensuring that they include cavity barriers that have not only been appropriately specified for the type of system they will be installed in but that have performance is backed by testing that reflects their end use can help to protect our built environment for generations to come.

At Siderise, we offer a suite of passive fire protection solutions specifically developed and tested to meet the demands of a wide range of rainscreen applications. We have also created a handy Specification Pack which provides live links to everything you need to select the right solutions for your rainscreen project, from technical data to design support.

If you want to dive deeper into this topic, register your interest for our RIBA credited CPD - [email protected]

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response