Controlling sound in noisy environments

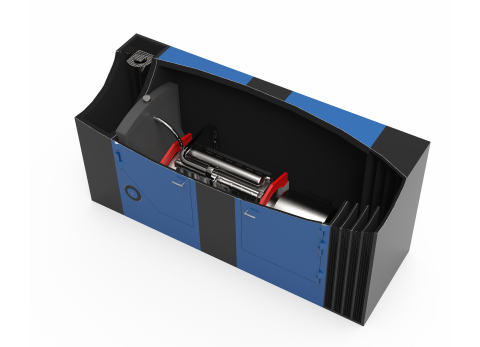

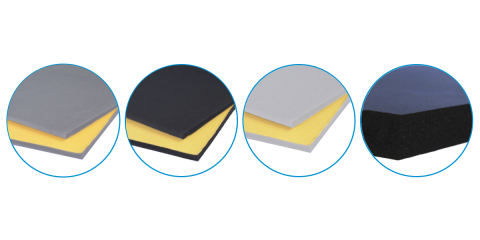

Noise management solutions for a wide range of applications

With our 50 year history rooted in developing acoustic solutions, we are specialists in engineered products for managing sound transmission. We have a range of off the shelf products for common applications.

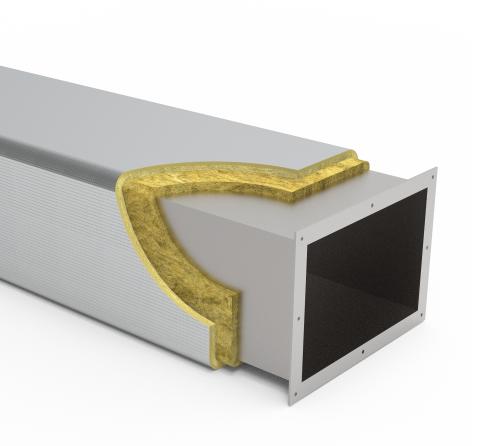

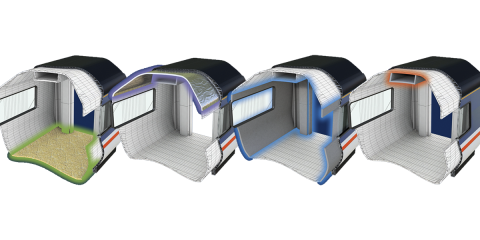

However, our expertise lies in working together with you to create bespoke solutions that meet your exacting specification criteria, whether it be for a train, a boat, a concert hall, a HVAC system or other industrial application.

Contact us

We're here to help you

Talk to us

Call for our main switchboard

Ask technical

Email us for technical enquiries

Ask site services

Email us for site support

Complete a form

Complete the form for the right response

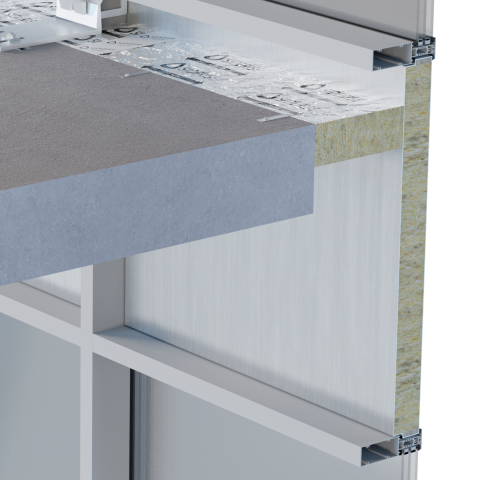

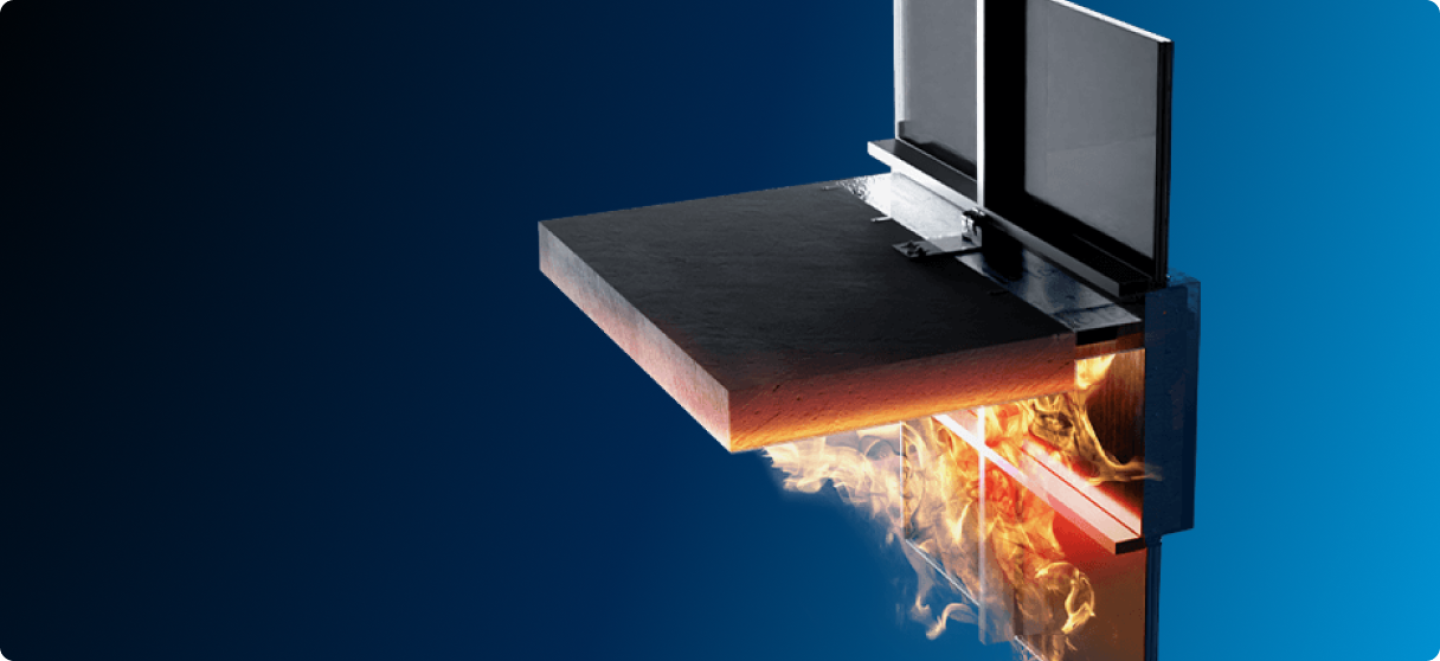

Passive fire protection

Did you know we have a number of passive fire protection solutions for curtain wall systems?