Commercial Administrator

Why is positive mechanical retention

key to the performance of

open state cavity fire barriers?

Horizontal open state cavity barriers (OSCBs) are critical to the safety and performance of all kinds of ventilated façade systems, from masonry to rainscreen. In day-to-day use (sometimes referred to as the ‘cold state’), they allow for free-flowing air movement and moisture egress. In the event of a fire, the intumescent edge, activated by heat at circa 140°C, exfoliates to create a fire seal. However, to be able to provide this protection for the lifetime of the building, OSCBs are required to be appropriately and robustly fixed to the internal substrate with a retention method that prevents barrier displacement — allowing them to preserve the specified air gap in the cold state and maintain integrity during fire exposure.

In this Insights piece, we will explore why the fixing method of OSCBs is a critical factor that should not be overlooked during the design and specification process.

How can the fixing method impact the performance of open state cavity barriers?

Buildings and façades are constantly subjected to forces that can cause them to move— including wind loads, temperature changes and settlement. In a fire, heat-induced air pressure and thermal expansion will place further stress on fixings. If these fixings lack sufficient tensile strength or retention capability, these factors can all potentially cause them to fail and the OSCBs to completely or partially detach from the internal construction.

This cavity fire barrier displacement can cause various problems, including:

Possible thermal efficiency and moisture management issues due to fallen cavity fire barriers obstructing ventilation and drainage flow in the cavity.

Compromised compartmentation allowing fire and smoke to spread vertically through the unseen cavity due to gap formation between the substrate and the rear of the barrier.

Severe misalignment of the OSCB that can lead to its intumescent layer not exfoliating within the limits of its stated air gap range, thus failing to form a complete seal against the opposing surface by not fully closing the width of the void.

To mitigate these risks, OSCBs must be selected with support brackets and fixings that are designed to keep them securely in position even when subjected to differential movement or fire-induced stresses, and that allow for the intumescent to fully exfoliate when exposed to the heat of a fire.

What fixing approaches are typically used for open state cavity barriers?

UK legislation does not give prescriptive requirements as to the fixing method. However, guidance, both statutory and specialist, all advocate for cavity barriers to be mechanically fixed in position. There are several common approaches to mechanically fixing cavity barriers:

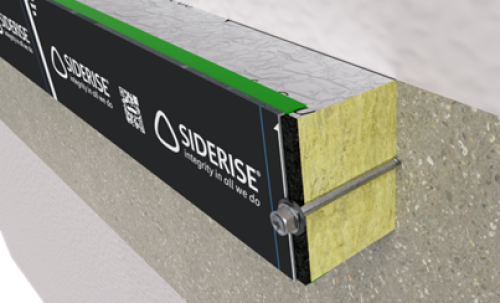

Direct through-fix to substrate using non-combustible fixings (small voids) – usually stainless-steel countersunk head screws with washer sitting flush with intumescent face and screwed at a sufficient depth into substrate.

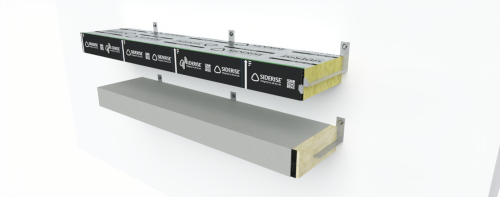

Mechanically fixed partial penetration brackets (large voids) – usually stainless-steel spikes that penetrate the width of the barrier by typically 50-75% and fixed to the backing wall using non-combustible stainless-steel fixings, sometimes with pigtail screws piercing through the intumescent into the barrier.

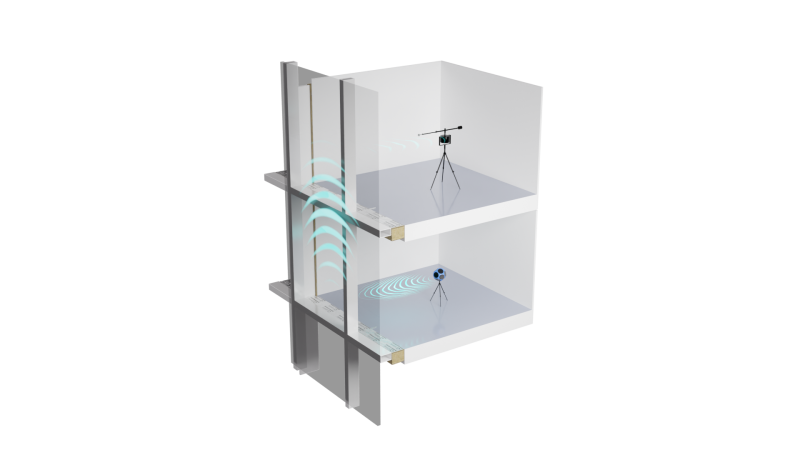

Mechanically fixed full penetration brackets with bent tails (large voids) – as above without pigtail screws but with ‘tails’ piercing through the intumescent on the leading edge of the barrier that faces the open airspace of the cavity. These are bent flat, or ‘counter folded’, to the outer face to positively retain the barrier and the intumescent.

Figure 1: For small voids, open state fire barriers tend to be fitted using a direct through fix to the substrate.

Figure 2: Side by side comparison of mechanically fixed full penetration brackets with bent tails (top) and mechanically fixed partial penetration brackets (bottom) in large voids (for illustration purposes only).

Fixing guidance in Approved Documents B (separate editions for England and Wales), Technical Booklet E (Northern Ireland), and Technical Guidance Document B (Republic of Ireland)

These all require cavity barriers to be tightly fitted to a rigid construction and mechanically fixed in position. They go on to say that they should be fixed so that their performance is not rendered ineffective by failure of the cavity barrier fixings during a fire, building and external envelope movement, or the collapse of penetrating services or failure of abutting construction. This means that they need to be retained securely using suitable fixings, and without support from the envelope.

Fixing guidance in Centre for Window and Cladding Technology (CWCT)

This statutory guidance is reinforced by advice from CWCT in both its Technical Note 98 Fire performance of façades - Guide to the requirements of UK Building Regulations and Guidance on Built-up Walls publications, which cover several façade types including curtain wall and rainscreen. It advocates more specifically for open state cavity barriers used within ventilated façades to be fixed with brackets that penetrate the full thickness of the barrier with tails bent over to positively retain the barrier in position.

For instance, Section 6.6.3.2.3. of Guidance on Built-up Walls that focuses on cavity barriers in rainscreen constructions states:

“To be effective, these should be securely fixed to the face of the back wall or preferably, for cavity barriers on the line of compartment floors, the concrete slab edge. This will require a break in the thermal insulation in the rainscreen cavity... Steel spikes are used to fix the barriers, and these should penetrate the full thickness of the barrier with the tails turned over to positively hold the barrier in position. Failure to do this may allow the barrier to fall down the cavity making it ineffective as a fire barrier and possibly blocking drainage.”

In section 4.24 of the guidance, it cites instances where this issue has been encountered, demonstrating that this is a very real potential problem:

“Cavity barriers should be positively fixed in position to ensure their effectiveness. Cases of barriers sliding off spikes and collecting at the foot of the cavity have been reported.”

Why are positive full penetration mechanical retention brackets considered more robust than a partial penetration brackets?

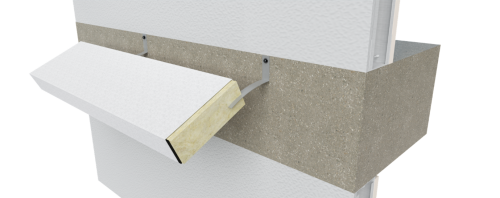

Using OSCBs with full penetration brackets that have retaining bent tails can support effective compartmentation in several ways. They enable the cavity barrier to be firmly secured to the substrate, preventing it from moving laterally during its service life. This allows it to maintain contact with the backing wall to provide an effective cavity barrier.

Figure 3. Diagram of how cavity barriers can slip off partial penetration brackets, leaving a gap between the barrier and the internal substrate (for illustration purposes only).

Full penetration brackets can also help to support the structural strength of the cavity barrier by allowing the weight of the barrier to be supported by the inner leaf, instead of relying on the tensile strength of the bracket alone. Additionally, an equilibrium is created between the barrier’s outer face and the bent tails when the bracket is fixed to the substrate above the OSCB, which can increase the structural strength of the OSCB to prevent sagging.

These types of brackets also offer benefits during the installation stage. As they do not rely on the external envelope for retention, they can be fitted at an earlier stage of the construction process to a less tight schedule. They are also much less likely to be dislodged or disrupted during the installation of the external envelope. It is also much easier for installers and inspectors to confirm if the OSCBs have been installed correctly. Some types of open state barriers, on the other hand, require hand-screwed pigtail screws to be wound out until they touch the inside face of the cladding – after the cladding has been installed

Did you know that Siderise RH Rainscreen Horizontal Open State Cavity Barrier comes with our RS Series Fixing Brackets? Available in galvanised or stainless steel, depending upon project requirements, they are supplied in a 25mm width in a range of lengths to suit the required void size. Learn more: https://www.siderise.com/fire-safety/ancillaries/siderise-rs-series-fixing-bracket

How can the installation quality of positive full penetration mechanical retention brackets be confirmed onsite?

The CIOB-RIBA Guide to Managing Safety-Critical Elements in Building Construction stresses the importance of inspecting cavity barriers as safety-critical elements, stating that:

“[F]or all Elements that contribute towards fire and smoke compartmentation of a building - The compartmentation must be assumed to be part of a considered design, so there could be a significant risk of a serious injury or fatality if it was compromised by incorrect installation and there was a fire. Therefore, the compartmentation in its totality is a Safety-Critical Element.”

Cavity barriers whose retention is reliant on the external facade being installed can present a challenge when it comes to inspection—requiring a section of the facade to be deconstructed to check how they have been fitted. Meanwhile, full penetration brackets with bent tails can simplify this process as their visible tails eliminate the need for destructive inspections in build ups where the thermal insulation abuts the open state cavity barrier from both above and below.

Figure 4: Installation of OSCB with positive retention bracket, demonstrating the visibility of the bent ends.

Siderise offers both in-person and remote inspections via our specifically developed Inspection App that allows users to capture images as each area / element is installed and update the data input fields using their smartphone or tablet. These can then be reviewed offsite by our technical team to ensure the installation meets recommendations and quickly identify any potential issues with the fixing methods.

What testing and certification should I consider?

As the fixing method is so integral to the performance of OSCBs, it is important to look out for products that have been subjected to testing with their fixing methods. This includes looking for products with a measured and defined design life, and that have been put through tests that replicate their intended application— demonstrating that they maintain integrity in real-world thermal and mechanical conditions.

The Association for Specialist Fire Protection (ASFP) Technical Guidance Document TGD 19 outlines the test configurations and failure criteria for the testing of OSCBs and the pending prEN 1364-6 standard which is being developed specifically for cavity barriers.

Figure 5: Siderise RH Rainscreen Horizontal Open State Cavity Barriers are tested and certified based on the use of fully penetrating brackets with retaining bent ends.

Whilst this test can determine standalone cavity barrier performance and therefore general suitability for the purpose it is marketed for, it is only through large-scale testing that we can fully understand how complete assemblies might perform in a real-life fire scenario. Such testing examines all the system components together, providing data on how the different products interact, along with the impact of details such as fixings, joints, gaps, and penetrations on the overall fire performance. Therefore, data from large scale systems tests such as BS 8414-1 & 2 and NFPA 285 that evaluate the performance of a complete façade assembly can be invaluable when considering any type of cavity barrier.

It is important to note that, even with the inclusion of positively retained cavity barriers, systems can fail if the external cladding allows the fire to spread up the outside of the building causing the panels to move, break down or come away. Any malfunction with the cladding would likely leave a path for the flames to spread up and over the cavity barrier and up the cavity. Therefore, it is vital to always refer to the latest specialist advice for façade design and specification, and to ensure high quality workmanship at every stage.

Siderise RH Rainscreen Horizontal Open State Cavity Barrier has been tested to ASFP TGD19 ‘Fire Resistance Test of Open State Cavity Barriers’ using principles of BS EN 1363-1. It has also featured in cladding systems assessed under multiple large-scale fire tests, including BS 8414 and NFPA 285.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Verifying the accuracy of your passive fire protection installations

Contractors play a pivotal role in ensuring passive fire safety strategies are delivered in the way they have been designed. Therefore, it is vital that onsite teams are not only equipped with the right knowledge and skills to install these life-safety critical products correctly, but that they have the tools to both demonstrate and verify the quality of the finished works.

This is especially crucial on projects subject to Gateway 3, requiring those involved in the construction phase to evidence that they have carried out the works in line with the design proposals signed off by the Building Safety Regulator (BSR). One way to do this is by taking advantage of Siderise’s free site support and inspection services.

Why is installation quality so critical to cavity barriers and firestops?

The Building Regulations requires buildings to be “designed and constructed so that the unseen spread of fire and smoke within concealed spaces in its structure and fabric is inhibited.” Passive fire protection measures within the building envelope can facilitate this by containing the spread of fire, heat, and smoke, creating areas of manageable risk— known as compartments— using fire-resistant materials and gap-filling measures like cavity barriers and firestops. This inhibits the movement of flames, smoke and hot gases from one compartment to another, protecting escape routes and reducing the risk of fire-induced structural damage which could result in collapse.

It is essential these solutions are installed properly to work as intended. Failure to do so could result in gaps in the compartment, providing an easy path for fire to spread up and around the building. Additionally, passive fire protection solutions not installed in accordance with their manufacturer’s recommendations may not achieve a project’s fire safety design requirement. This is because the installation will not be reflective of the way the products or systems have been designed and tested to perform.

How can I ensure that my team has the right competencies to install passive fire protection?

Ensuring accurate installation begins with equipping teams with the right knowledge and skills. As a general point, it is worth noting that, as installation contractors of passive fire protection systems are considered a ‘specialist trade, there are several independent schemes that can include training, third-party certification, and professional qualifications. Whilst voluntary, they are good practice and help to ensure a strong foundation of competency. These often include various assessments of both how projects are managed, how installations are carried out, and how they are overseen— in addition to annual audits and random site inspections. Depending on the schemes, they may also allow contractors to log their installations and issue certificates of conformity to the end client.

However, for teams wanting to know more about the specific methods and approaches needed to install Siderise products effectively, we offer a range of free product-specific training and support opportunities. These have been developed to provide installers with invaluable insight into the specifics of our products and systems, as well as potential build challenges— allowing them to be addressed before the installation programme has progressed and preventing issues being ‘baked into’ the construction.

This offering includes a combination of classroom learning and practical onsite training, covering everything from ‘toolbox talks’ that ensure installation instructions and method statements are clearly understood, to delivering hands-on training and benchmark installations to demonstrate best practice.

Furthermore, the recent launch of the Siderise Academy Online Learning Portal has made learning about our products more accessible with a range of on-demand courses, webinars, and CPD modules. Certificates of completion can be downloaded as evidence of training, supporting the need to increase the competency levels of individuals.

Also, being an ASFP Recognised Training Provider means our training material has been verified as technically accurate and relevant and can also be used within the ASFP Competency Pathway, leading to the ASFP Pass Mark.

How can you verify that this manufacturer guidance has actually been carried out onsite?

One of the historic challenges with verifying the quality of passive fire protection installations is the fact Building Control inspections typically happen at the end of the construction process when the passive fire protection products have been covered by the façade. Whilst on some projects, elements of the finished façade can be removed to check that cavity barriers and firestops have been installed correctly, this is not always possible depending on the façade type and how it is constructed. Also, these ‘spot checks’ don’t allow installation teams to demonstrate consistently high standards across the build— an important factor when looking at large projects such as high-rise buildings.

To mitigate these risks and demonstrate diligence throughout the project, installation teams can work with our Site Services engineers to regularly inspect the installation of our products. This free service can verify if Siderise products are installed in accordance with our installation guidance to ensure that they will perform as expected in the event of a fire. They can be carried out either in-person, with periodic visits and support from our trained and experienced site services engineers or via the Siderise Inspection App

This digital form of inspection is suitable for checking the installation quality of our standard passive fire protection and acoustic systems as the programme progresses. It allows users to capture images as each area / element is being installed and to update the data input fields using their smartphone or tablet. The app then immediately turns this into a comprehensive, easy-to-understand report which can be reviewed offsite by a technical team to confirm the installation meets recommendations and to quickly identify if any areas need remedial actions before the works progress. This prevents errors from being built in and helping to save time and money, whilst facilitating a consistently accurate installation across the project.

How can you log these training, inspections and support as part of the Golden Thread?

We can supply you with reports from our inspection services, as well as documentation about any advice contracting teams have received from our technical and site service engineers. These can be logged and shared with other project stakeholders and included in subsequent handover information, providing a clear digital record of exactly what’s in the building and how it was installed. This helps to maintain that vital ‘Golden Thread’ of product information, support Building Control and/or the Building Safety Regulator in ensuring the passive fire safety measures have been delivered correctly, and can be a useful reference point for any future modifications that may affect the building envelope.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Cutting through the noise: Acoustic considerations for curtain wall façades

Acoustic separation in curtain-walled buildings can be a challenge for façade designers and engineers. Often constructed using low mass materials such as lightweight and hollow aluminum profiles and glazed panels, curtain wall façade systems are particularly susceptible to flanking sound transmission. In other words, any noise transferred between rooms by a path other than via the separating partition. Curtain walls provide several such noise paths.

It is therefore important for designers and engineers to adopt well thought out acoustic strategies at the early stage of a project that considers the design of junctions between party walls and floors and the façade, as well as the transfer of noise through the façade itself. With proper consideration and good acoustic design, spaces abutting curtain walls can be acoustically comfortable and private.

How is sound measured?

Before we explore the principal flanking sound transmission paths in curtain walling systems, it is important to clarify some of the key measurements used when talking about building acoustics

All noise is measured in decibels (dB). However, decibel values alone do not give any indication as to the context of the noise being measured. For example, does a decibel value refer to the performance of a single element, or to an entire detail? Does it refer to airborne or structure borne noise? Does it inform us of the period over which the noise measured?

To provide clarification at a glance, ‘acoustic metrics’ are used. These appear as a short string of text that accompanies the dB value, for example 45dB DnT,w. Here’s a brief explanation of the metrics relevant to curtain wall acoustics:

dB Rw - weighted sound reduction index

This laboratory measured value identifies the airborne sound insulation performance of a single proprietary building element. It is used for internal or external walls, ceilings / floors, windows, doors or any other separating element. The higher the Rw value, the better the sound reduction performance of the element.

Because dB Rw is a laboratory measured value, it does not take into account any potential site issues such as tolerance or workmanship, nor any flanking noise paths, which may be present onsite. This means that the Rw performance of an element in a laboratory setting is typically higher than what the element can achieve in the context of a full detail.

dB Dnf,w – Weighted normalised flanking level difference

This laboratory measured value represents the performance value of a flanking element only, for instance, a curtain wall façade, raised access floor or suspended ceiling. Any noise transferred between rooms through noise paths other than the separating partitions is flanking noise.

dB DnT,w - Weighted standardised level difference

This is a site measured value that represents the total airborne sound insulation between a given pair of rooms and accounts all noise paths, both direct noise through the separating partition and flanking noise through any other path.

The DnT,w test includes a correction to account for the reverberation time - or echo - in the rooms being tested. This allows acousticians to compare measured sound insulation results between different rooms and at different times, while accounting for the relative room size and any changes to furnishings applied when the room is in use, for example the presence of furniture and soft finishes like carpets and curtains.

How does noise travel through curtain wall systems?

With these metrics in mind, we can take a closer look at the main five paths through which noise travels in curtain wall façade systems. The façade’s Dn,f,w performance is influenced by each of these, and the achievable performance would be limited by whichever of these noise paths is the weakest.

Glazing

Sound waves are incident on a pane of vision glass, causing the glass to vibrate. These vibrations travel through to adjacent rooms via the structure of the glass itself and re-radiate as noise. Noise that travels via solid materials in this manner is called structure borne noise. Glazing type, spans of glass and spandrel panels, the number of separating transoms and their stiffness, all influence how sound travels along this path.

Transoms

Most curtain walling systems use aluminium profiles. These framing elements are relatively lightweight and sound energy incident on them may easily break through them into adjacent spaces. The height and construction of spandrel panels as well as the transom design and number of separating transoms affect how sound travels along this path.

The mullion joint

Sound energy hits the mullion causing it to vibrate. These vibrations (structure borne noise) travel along the mullion and radiate into adjacent rooms. The design of the mullion joint is the most significant factor in how this noise path performs.

Continuous mullions can be a significant limiting factor* on achievable performance.

Mullion hollow

If sound energy hits the mullion and passes through into the hollow profile, it can travel up and down the building before re-emerging in another space. The hollows of mullions create a hidden pathway for unwanted noise.

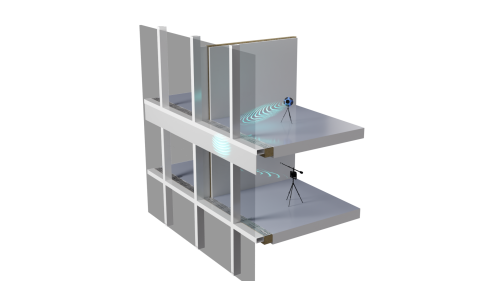

Perimeter joint / Movement gap / Firestop zone

The essential gaps at the joints where different building elements meet e.g. at the slab edge / façade interface, accommodate building movement and fire protection measures, but they can also present a path for flanking sound transmission. Carefully designing and treating these zones with high mass and isolating materials with fire-resistant properties is crucial for achieving good sound insulation as well as meeting the required fire resistance performance.

*It’s important to note that the overall performance of a curtain wall system is only as good as its weakest link. This is known as the performance-limiting factor (PLF). Addressing the weakest sound transmission path is crucial for achieving substantial improvements in noise control.

What noise mitigation measures should you consider when designing and specifying curtain wall façade systems?

Splitting mullions at floor levels

A significant increase in potential overall performance can be achieved by decoupling the mullions at the floor level. This can be achieved by splitting then rejoining mullions with joining spigots at the floor line.

Generally, splitting the mullions in the floor zone is necessary for achieving levels of flanking performance suitable for most residential and commercial projects.

Twin transom design

Single transom designs will limit the possible overall floor-to-floor performance. Using twin transoms instead can help reduce noise transmission through these elements.

High-performance glass

Specifying glass with higher acoustic properties is usually done to mitigate noise transmission from outside to inside but can also be beneficial for flanking noise within the building.

High-mass treatments

Incorporating materials with higher mass, such as acoustic matting or panels at the slab edge can significantly improve floor to floor acoustic performance.

Decoupled framing

Physically separating framing elements from surrounding structures can effectively reduce noise transfer through structural connections.

What noise control mechanisms are available for curtain wall systems?

Investing in acoustic products with proven performance is critical. The standalone acoustic performance of materials and products are typically rated using dB Rw. Whilst the exact performance requirements and product selection will depend on the project, choosing solutions which have been designed, developed and tested specifically for noise control in curtain wall applications can help ensure compatibility.

At Siderise, we have developed a range of products that are specifically designed to address the acoustic issues associated with curtain wall systems, as well as ensuring their passive fire protection. These include:

MI Mullion/Transom Acoustic Insert

Inserting acoustically absorptive inserts within hollow mullions and transoms can reduce noise transfer through these internal cavities. Various solutions are available to suit different curtain wall configurations and noise control applications.

This is an external treatment that can be used to overclad curtain walling mullions where there are abutting partitions. This can substantially improve acoustic performance through the mullion. MC is also available as a fire-rated variant which can provide up to 2 hours EI fire resistance.

As a decorative treatment, MC can be colour-matched to the façade. It is ideal for projects where acoustic infill upgrades to the mullion are not practical such as retrofits and situations where the internal layout is unknown during construction, or when fit-out or operation has already begun.

An acoustic panel developed to reduce noise transmission at the junction between internal partitions and curtain walls or window mullions. It provides a slim solution where high dB Rw performance is needed.

Acoustic Barriers (CW-AB, CVB/C10)

Installed beneath CW-FS Curtain Wall Firestops functioning as a perimeter fire seal at the edge of the floor slab, it can effectively reduce floor-to-floor sound transmission. Unlike traditional mass-barrier materials such as steel or plasterboard, our barriers can accommodate façade movement.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

On

0

On

0

On

0

On

0

Off

0

Off

0

On

-5

On

-5

Off

5

Off

5