Reliable solutions for safer, more comfortable buildings

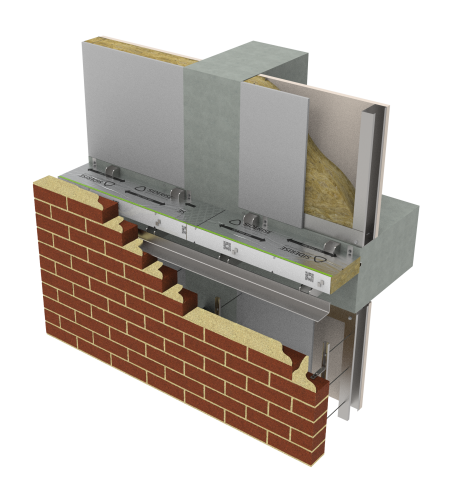

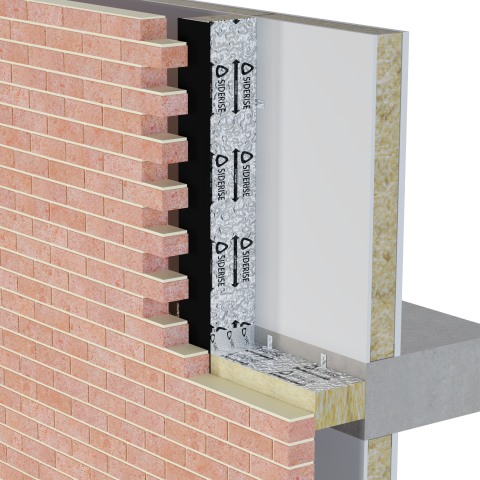

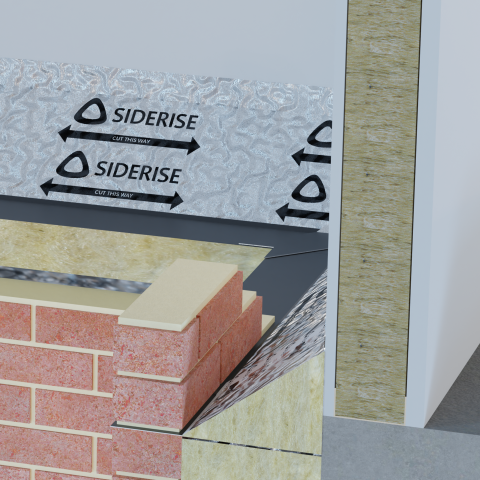

Passive fire protection and cavity trays for external masonry walls

Brick, stone, and concrete have been used for centuries thanks to their robust characteristics and timeless aesthetic. However, as the demands on our built environment have changed, so have the ways we approach masonry construction, how it manages moisture and how that can impact on fire safety.

Our solutions protect all kinds of masonry building approaches — from traditional brick and block to steel framed constructions — without compromising on design flexibility or installation efficiency.

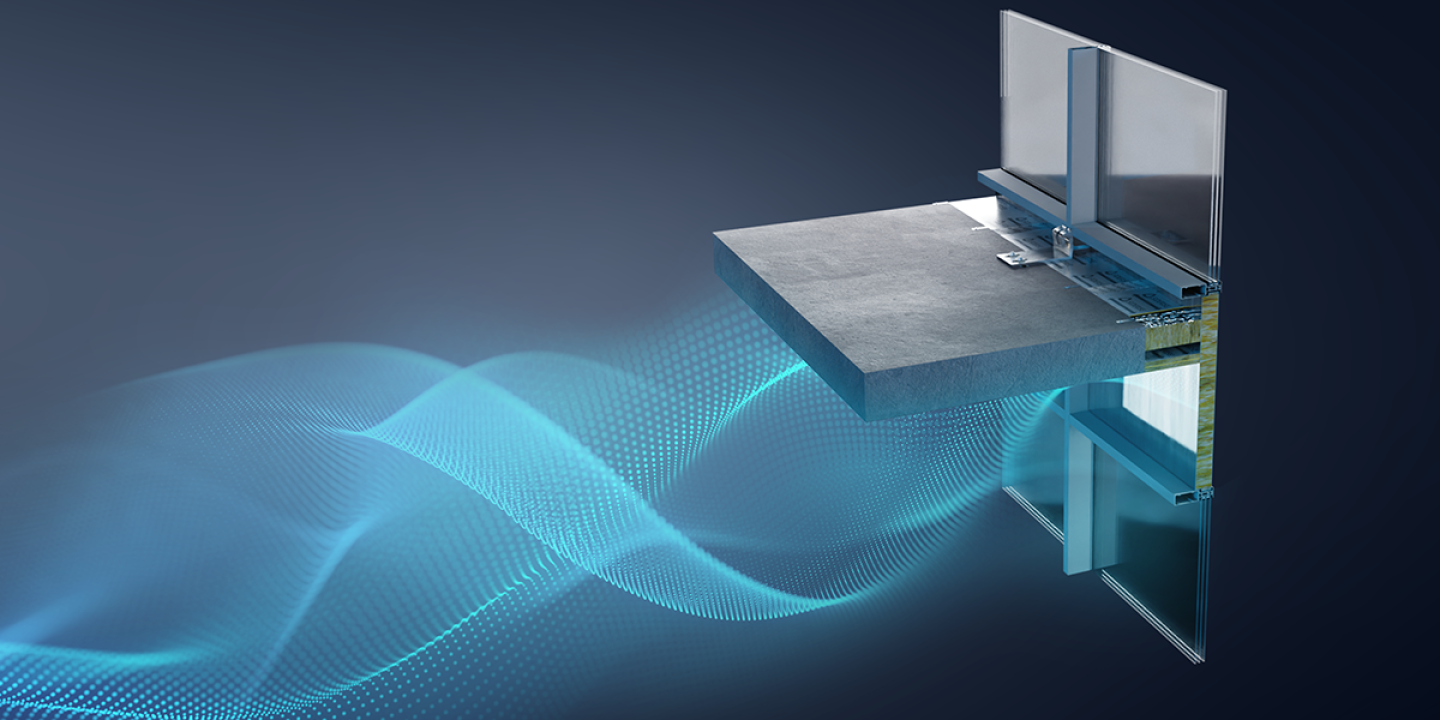

Acoustic Solutions

Did you know we have a number of acoustic solutions for curtain wall systems?

Contact us

We're here to help you

Talk to us

Call for our main switchboard

Ask technical

Email us for technical enquiries

Ask site services

Email us for site support

Complete a form

Complete the form for the right response