Robust solutions for meeting the demands of glazed façade systems

Passive fire protection for curtain walls

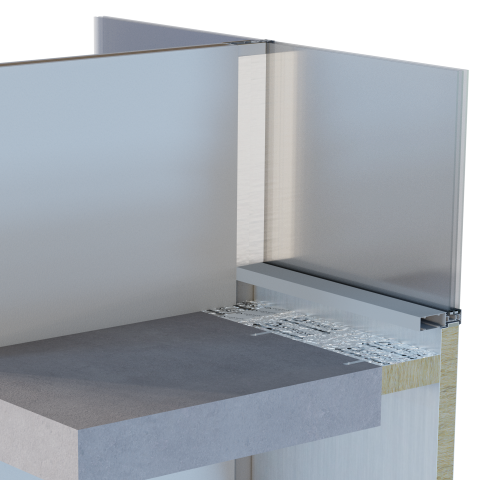

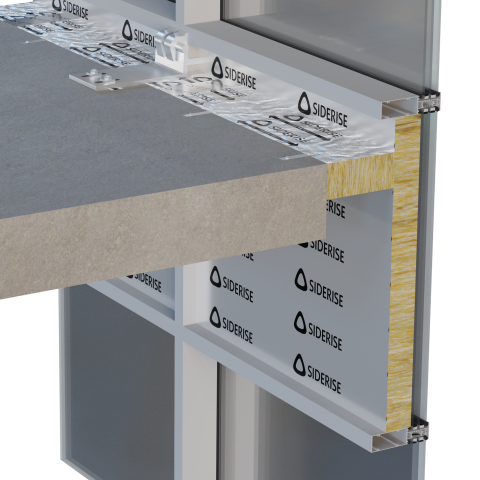

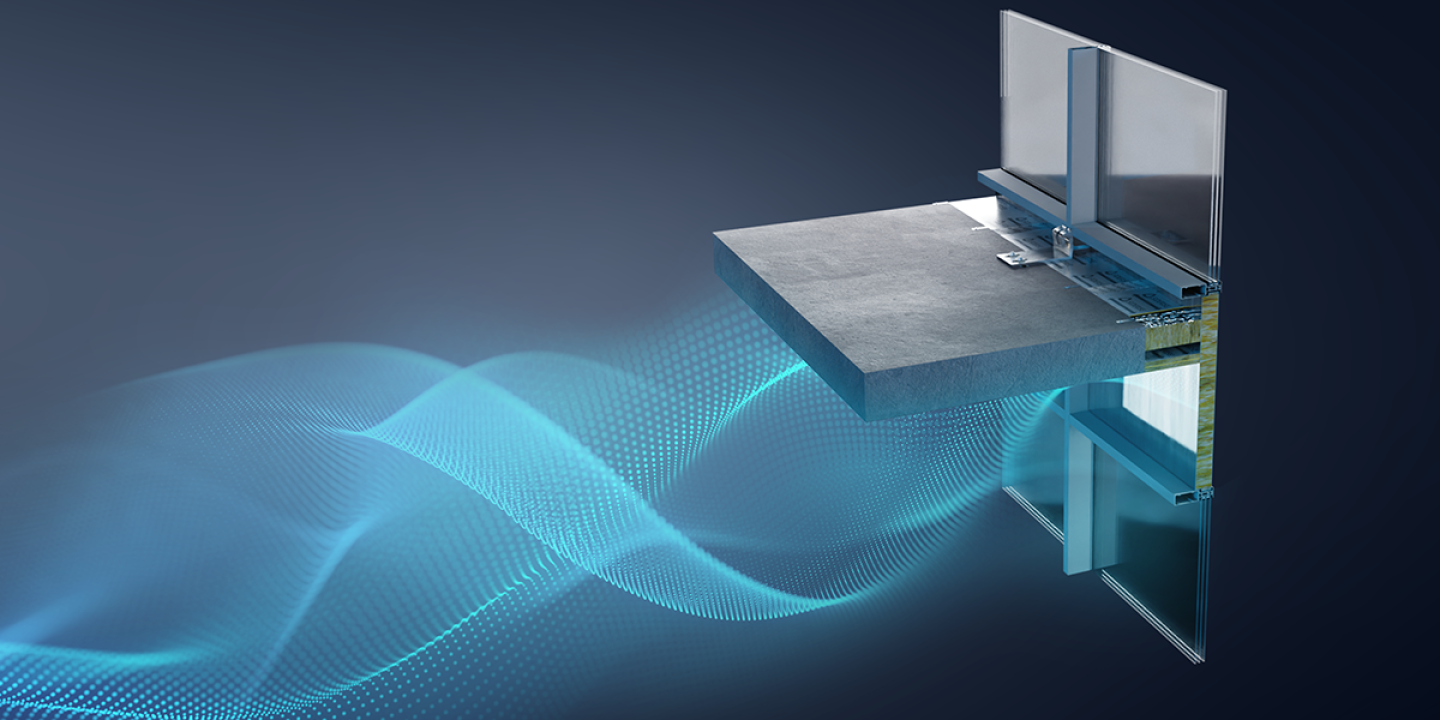

Curtain walling serves as a non-structural façade system with a sleek aesthetic for the exterior of mid to high-rise buildings, protecting occupants from the external elements whilst offering them floor-to-floor natural daylight. For long-term fire safety, it is important that these glazed façade systems include compartmentation solutions that not only provide reliable fire resistance but are designed and tested with building movement and façade deflection in mind.

Our comprehensively tested range of passive fire protection products and systems for curtain wall façades are specifically engineered to deliver the fire resistance performance needed for what are typically non-fire rated ‘window framed’ building envelopes.

Acoustic solutions

Do you know about our acoustic treatments for curtain wall systems?

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response