What is Siderise stone wool Lamella?

Get to know our unique, revolutionary cavity barrier and firestop insulation technology

Always on top form

There are several types of stone wool firestop and cavity fire barrier solutions available for different applications. It is vital that these safety-critical products function to not only deliver the necessary fire performance but also achieve and maintain good form and fit for the lifetime of a system, even when subjected to building movement.

In 1991, Siderise founder, Steve Bond, developed a unique automated ‘high speed lamella’ manufacturing process to engineer products that could do just that.

What makes Siderise Lamella so special?

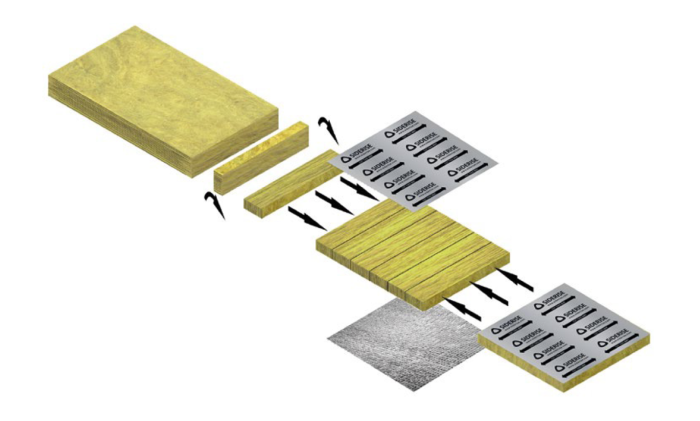

Siderise’s Lamella features a special formulation of stone wool insulation with vertically oriented fibres, instead of a horizontal fibre structure.

These vertical fibres are laterally compressed under quality-controlled factory conditions to assist with uniform density and remove any gaps between the adjoining cut sections, which may otherwise result in weakness. This ‘pre-compression’ is held in place by carrier facings (typically foil), which are heat applied to the cut faces of the fibres.

The result of these pre-compressed vertical stone wool fibres that sit perpendicular to the substrate in application is manifold in terms of performance characteristics. This includes a durable and resilient one-piece, dry-fit fire barrier solution; a tight fit; the ability to withstand building and façade movement; mitigating the risk of cladding panels bulging after panel installation; eliminating the need for a secondary wet seal; and facilitating a quick and simple installation process with straightforward compression in voids alongside our friction fit product ranges.

Why is Lamella used in Siderise products?

As accelerated age testing in accordance with EOTA Technical Report 024 demonstrates, the vertical fibre structure of Siderise Lamella allows our products to be laterally compressed repeatedly, with no loss of recovery / flex. This gives them the ability to accommodate in-service movement, allowing the integrity of seal within the gap to be constantly maintained, ensuring effective fire compartmentation for the lifetime of the building.

The video below shows this in action.

Siderise Lamella around the world

Our manufactured products with the vertical fibre structure and unique pre-compression provide a combination of installation and performance benefits on a wide variety of building envelope types— including curtain wall, rainscreen and masonry. These products have also gone through decades of third-party testing to ensure market leading performance. This integrity in our product performance plays a significant role in revolutionising how we protect the high-rise buildings which define the world’s skylines.

Innovation at our core

To this day, we are using our in-depth knowledge of passive fire protection to develop new solutions and approaches.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response