Siderise RH Brick Slip Horizontal Open State Cavity Barrier

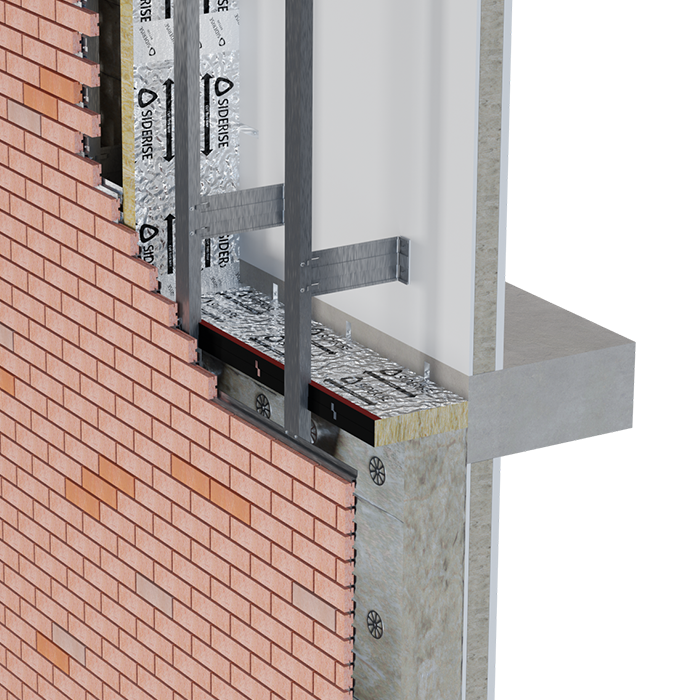

Positively retained mechanical fix open state cavity barrier for restricting vertical fire spread whilst aiding ventilation and drainage in brick slip cladding systems.

Balancing ventilation and drainage with fire compartmentation

Siderise RH Brick Slip Horizontal Open State Cavity Barrier comprises a stone wool lamella core with vertically oriented fibres and an intumescent strip on its leading edge encapsulated within a colour coded polymer film.

In normal service conditions, it allows ventilation and drainage of the cavity by leaving a gap behind the outer brick slip skin but closes the cavity in the event of fire to provide fire separation. The intumescent layer activates at around 130°C and starts to exfoliate until it fully closes the gap to form an effective fire seal within 5 minutes.

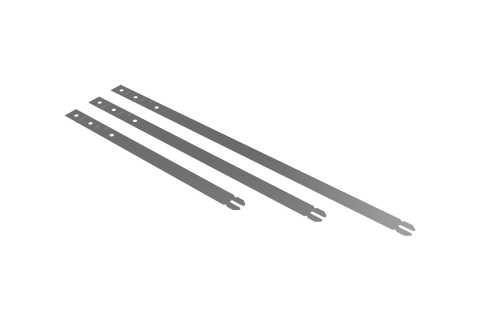

Full-penetration mechanical fix brackets with bent tails for positively retaining the barrier help prevent it from shifting forward and ‘slipping’ off, thus reducing the moisture build-up risk associated with obstructing ventilation and drainage flow in the cavity, and also reducing any additional fire risk that can result from the formation of unprotected gaps between the substrate and barrier.

The fixing method used to tightly secure the barrier to the internal structure enables them to remain firmly in place during the building’s lifetime, thus satisfying the mechanical retention requirements set out in the statutory guidance for fire safety in England, Wales, Scotland and Northern Ireland, as well as the advisory guidance published by CWCT.

RH Brick Slip Horizontal Open State Cavity Barrier has undergone EOTA TR 024 ‘Type X’ accelerated age testing to the harshest category, which replicates exposure to rain, UV, high temperatures, and frost and thaw cycles, to confirm long-term durability and suitability for buildings with a design life of 60 years or less.

Manufactured in accordance with the framework standard for the responsible sourcing of construction products, BES 6001, to certification level ‘Good’, supporting the qualification for credits in sustainable building programmes such as BREEAM, LEED and DGNB.

RH Brick Slip Horizontal Open State Cavity Barrier has been evaluated through a lifecycle assessment (LCA) to determine its environmental impact, which is published in an independently verified Environmental Product Declaration (EPD) prepared in accordance with BS EN 15804+A2: 2019 and ISO 14025/ISO 21930.

Comprehensively tested to ASFP TGD19 ‘Fire Resistance Test of Open State Cavity Barriers’, it offers a range of insulation and integrity performance options to suit different project requirements. It has also undergone project-specific testing to confirm compatibility with various brick slip manufacturer systems.

Its fire resistance performance is IFC certified (IFCC 1712), and its reaction to fire performance to BS EN 13501-1: 2018 is Intertek US and UK certified.

Tested within ventilated brick-slip cladding systems the Siderise Brick Slip Cavity Barriers comprise of the RH Brick Slip Horizontal Open State Cavity Barriers and the Siderise RV Brick Slip Closed State Vertical Cavity Barriers. Their combined use ensures that the brick slip system will drain moisture within the façade construction whilst maintaining airflow in normal service.

Siderise RH Brick Slip Horizontal Open State Cavity Barriers incorporate a continuous high performance reactive intumescent strip which is bonded to the leading edge. In the event of fire, the intumescent rapidly expands and fully seals the purposely designed ventilation gap, between the barrier and the rear of the cladding, formed at the time of installation.

RH Brick Slip Horizontal Open State Cavity Barriers are compliant with current market requirements and has been tested to ASFP Guidance: ’Open State’ Cavity Barriers used in External Envelope or Fabric of Buildings, utilising principles of EN 1363-1, referred to as ASFP Technical Guidance Document –TGD 19 (EN 1364-6).

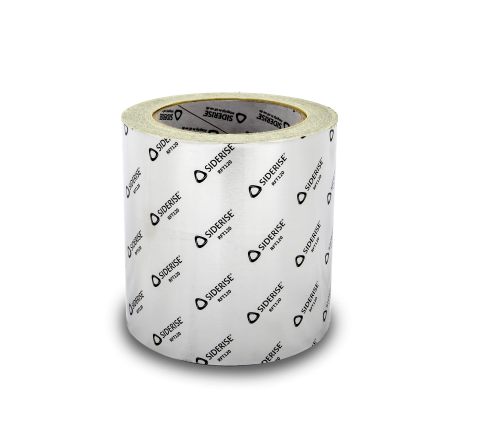

Intersections between the RH Brick Slip Horizontal Open State Cavity Barrier and RV Brick Slip Closed State Vertical Cavity Barriers are simply abutted, with RFT 120/45 foil tape applied as detailed in installation instructions provided separately.

Siderise RH Brick Slip Horizontal Open State Cavity Barriers consist of a non-combustible stone wool lamella core, with reinforced aluminium foil faces.

The primary seal has a reaction to fire performance of Class 'A1' to BS EN 13501-1:2018, while the continuous intumescent strip on the exposed edge has a reaction to fire performance of Class ‘E’ to EN 13501-1 enabling it to react rapidly and close the purposely designed ventilation gap in the event of fire. This is permitted by Regulation 7(3)(f) - Approved Document B for England & Wales.

The exposed leading edge is also sealed with aluminium foil & additionally encapsulated in a polymer film. As standard, the film is black to register as a ‘shadow-line’ behind open joints in the cladding.

Whilst the base material is water repellent and non-hygroscopic, this predominantly enclosed arrangement affords an added degree of weather protection to the core material. It is designed to leave an air gap for moisture drainage and allow ventilation in the brick slip cladding system but provide a seal in the event of a fire.

The standard product length for both horizontal and vertical cavity barriers is 1200mm. Whereas horizontal barriers are only available as precut strips, vertical barriers are also available in sheet form.

For product identification purposes, the top edges of the film used on the RH cavity barriers are colour-coded and labelled to show the product fire performance rating. Please see Table 1.

Brick Slip Systems / Project Level Testing

Brick slip systems typically contain a series of rails to support the outer brick slips. These brick slips can also incorporate voids or ‘frogs’ within them. It is important that even if specifying facades under the ‘linear route’ within Approved Document B, that consideration is given to the hidden voids created by these rails and brick slip ‘frogs’.

Therefore, we recommend partnering with us to test specific systems at our Innovation Centre. These project level test reports can then be used as supporting evidence by the project fire engineer and design team.

It may be the case that our existing test library provides support for a given project arrangement, please consult our standards details and engage with our Technical Services team for clarification.

Reaction to fire

This is the response of a material in contributing by its own decomposition to a fire to which it is exposed under specified conditions. Results are classified to BS EN 13501-1:2018 “Fire classification of construction products and building elements”.

The primary element of the seal (stone wool with aluminium foil facings) used in Siderise RH Brick Slip Horizontal Open State Cavity Barriers have a reaction to fire Third-party certification with Intertek and are classified as ‘A1’ to EN 13501-1.

The intumescent has a reaction to fire classification of ‘E’ to EN 13501-1 enabling it to react rapidly and close the purposely designed ventilation gap in the event of fire. This is permitted by Regulation 7(3)(f) - Approved Document B for England & Wales.

Resistance to Fire

This is the ability of an element of structure or product to maintain its stability for a specific time period as determined by ‘integrity’ (E) and ‘insulation’ (I) as specified in the fire resistance test. Where appropriate results can then be classified in accordance with EN 13501-2.

Siderise has tested RH Brick Slip Horizontal Open State Cavity Barriers with a 25mm air gap to the ASFP TGD19 method. During the fire tests, the seals achieved full effective closure in under 5 minutes. Seal temperatures remained below a 180°C rise during this activation period and maintained the EI requirements for up to E 120 and I 120. See Table 1 for details.

Please note: the fire resistance performance for RH Brick Slip Horizontal Open State Cavity Barriers, given in Table 1, relate to the performance of barrier in isolation, the overall performance of the system should be reviewed by Technical Services, with additional project level test evidence provided via the Siderise Innovation Centre if necessary.

Please see below tables for product fire performance ratings and applicable void sizes:

Table 1 : RH Fire Resistance to General Principles of ASFP - TGD 19 (EN 1364-6)

| Product Ref | Colour | Max Air Gap (mm) | Integrity (mins) | Insulation (mins) | Barrier Thickness (mm) | Max Void (mm) | Third-party Certification |

|---|---|---|---|---|---|---|---|

|

RH25-120/90 |

Grey |

25 |

120 |

90 |

Intumescent strip (1.5) |

25 |

IFCC 1712 |

|

RH25-90/30 |

Green |

25 |

90 |

30 |

75 |

425 |

IFCC 1712 |

|

RH25-60/60 |

Orange |

25 |

60 |

60 |

90 |

425 |

IFCC 1712 |

|

RH25-120/120* |

White |

25 |

120 |

120 |

120 |

425 |

IFCC 1712 |

|

RH50-60/60 |

Blue |

50 |

60 |

60 |

Intumescent strip (3.0) |

50 |

IFCC 1712 |

|

RH50-30/30 |

Red |

50 |

30 |

30 |

75 |

300 |

IFCC 1712 |

|

RH50-60/60 |

Blue |

50 |

60 |

60 |

90 |

300 |

IFCC 1712 |

* Tested with min. 50mm thick stone wool thermal insulation (classified A1 to EN 13501-1) above and below the cavity barrier. See IFC Certification IFCC 1712 for further details.

Table 2: RH Fixing requirements and barrier dimensions

| Product Range | Void Range (mm) | Air Gap (mm) | Barrier Width (mm) | Length (mm) | Fixings |

|---|---|---|---|---|---|

|

RH25 |

≤ 25 |

≤ 25 |

Intumescent strip (1.5) |

1200 |

3no. Screws |

|

26 - 40 |

≤ 25 |

15 |

1200 |

3no. Screws |

|

|

41 - 45 |

≤ 25 |

20 |

1200 |

3no. Screws |

|

|

46 - 75 |

≤ 25 |

Void - 25 |

1200 |

3no. Screws |

|

|

76 - 250 |

≤ 25 |

Void - 25 |

1200 |

3no. RS 350 G/S |

|

|

251 - 350 |

≤ 25 |

Void - 25 |

1200 |

3no. RS 450 G/S |

|

|

351 - 400 |

≤ 25 |

Void - 25 |

1200 |

3no. RS 550 G/S |

|

|

RH50 |

≤ 50 |

≤ 50 |

Intumescent strip (3.0) |

1200 |

3no. Screws |

|

51-65 |

≤ 50 |

15 |

1200 |

3no. Screws |

|

|

66 - 70 |

≤ 50 |

20 |

1200 |

3no. Screws |

|

|

71 - 100 |

≤ 50 |

Void - 50 |

1200 |

3no. Screws |

|

|

101 - 250 |

≤ 50 |

Void - 50 |

1200 |

3no. RS 350 G/S |

|

|

251 - 300 |

≤ 50 |

Void - 50 |

1200 |

3no. RS 450 G/S |

The above fire performance relates to product only testing to TGD19, the overall void used within the system should be reviewed by Technical Services and supported by additional system specific project testing if necessary.

- Brackets are available in two forms: (G) denotes galvanised steel brackets and (S) denotes stainless steel brackets.

- Brackets must be installed at 400mm centres based on a 1200mm strip. For lengths ≤800mm 2no brackets must be used, with spacing reduced pro-rata. Lengths <100mm should be avoided by cutting down the adjacent barrier accordingly.

- All brackets are to be suitably fixed to the substrate with non-combustible fixings.

- All brackets penetrate the product at mid-thickness. The protruding split ends should be counter-folded to retain the product, except for RH50-60/60 and RH25-120/120. For RH50-60/60, ensure the split end facing down overlaps with the intumescent face. For RH25-120/120, the bracket should overhang the barrier by 15mm then one of the split ends should be bent upwards and the other trimmed flush with the leading face of the barrier.

- Please refer to separate RV-RH installation instructions.

Table 3: RH Product Properties

| Properties | Value |

|---|---|

| Form Supplied |

1200mm long. Supplied pre-cut in width to suit advised void size reduced by the ventilation gap required. |

| Product Finish |

Aluminium foil tape to top and bottom surfaces |

| Appearance |

Coloured tapes to indicate performance |

| Reaction to Fire |

The primary stone wool seal is Classified 'A1' to EN 13501-1 The reactive intumescent along the leading edge is Class 'E' to EN 13501-1. This is permitted by Regulation 7(3)(f) - Approved Document B for England & Wales. |

| Resistance to Fire |

For product fire performance see Table 1 |

- Stone wool core is recyclable.

The following information is available for download via the website:

- Material Data Sheet

For technical advice, support, or classification reports please contact the technical team: [email protected]

For Installation Training or Site Inspections please contact: [email protected]

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Augmented Reality

Point your camera at the QR code. Tap the banner that appears on your screen.