What is passive fire protection?

Passive fire protection, also known as ‘built-in’ fire protection, has been used in buildings throughout history, even as far back as Ancient Rome, where Emperor Nero is said to have ordered the rebuilding of the city with fire-resistant materials and increased separation between buildings after large parts of it were destroyed in a fire. Today, it is still a crucial and often legal requirement in protecting a building’s structural integrity and its neighbouring environment.

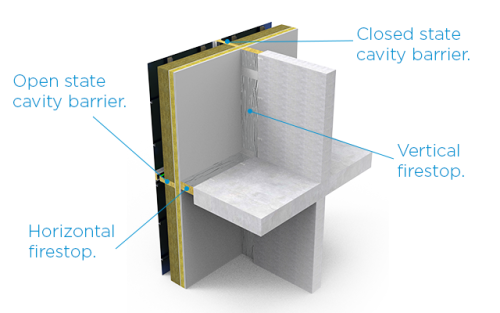

Passive fire protection encompasses a broad range of systems from intumescent coatings for insulating structural steel to fire resisting glazing and ductwork, which in the main do not require activation or a command signal to function – hence the term ‘passive’. In this blog, we answer common queries on the passive fire protection elements we specialise in— cavity barriers, firestops and linear gap seals that go into the building envelope.

What does ‘passive fire protection’ mean?

Different definitions may vary slightly; however, the essence is fundamentally the same. The Association for Specialist Fire Protection (ASFP) defines passive fire protection as:

“Passive Fire Protection is built into the structure to provide stability and into walls and floors to separate the building into areas of manageable risk— compartments. These areas are designed to restrict the growth and spread of fire, allowing occupants to escape and offering protection for firefighters. Such protection is either provided by the materials from which the building is constructed or is added to the building to enhance its fire resistance.”

The primary purpose of cavity barrier, firestopping and linear gap seal passive fire protection measures is to control the spread of fire and smoke for a defined period of time by providing compartmentation – the first line of defence in a fire strategy. In this context, the intention of compartmentation is to prevent the spread of fire to or from another part of the same building, or an adjoining building, by containing fire to the compartment of origin. Effective compartmentation requires imperfections in the building, or breaches to walls and floor e.g. joints, to be adequately sealed so that the compartment line is reinstated.

Why is passive fire protection crucial in the building envelope?

When thinking about minimising fire risk in high rise buildings, it is easy to focus on the most apparent and visible fire control measures such as alarms, fire extinguishers and sprinkler systems. However, without appropriate passive fire protection, fire can spread quickly via the building structure.

This can either be via the surfaces, or unseen through the concealed cavity between the inner structure and the outer envelope, which can act almost like a chimney, drawing flames, heat, and smoke up the building. This makes the fire much more difficult to keep under control and could lead to people being unable to escape, causing significant structural damage to, or even collapse of, the building.

What is the difference between active and passive fire protection?

Active fire protection covers any detection or suppression product, or system actively working to identify and alert that there is a fire, or to suppress a fire to control its temperature such as fire extinguishers, ventilation, sprinkler / mist systems and smoke alarms.

It is easy to differentiate when focusing on the terms ‘active’ and ‘passive’. In essence, active products require a form of action and passive products work in the background, requiring little or no interaction or activation (NB there are some anomalies with systems such as fire curtains, fire and smoke dampers and some types of doors that are designed to operate from such methods).

While these active fire protections are extremely important for a building’s fire safety, for a balanced fire strategy, they should be used in conjunction with passive fire protection to ensure the building envelope has fire safety precautions throughout.

Who is responsible for passive fire protection?

Ultimately the building owner is responsible and accountable for all building safety aspects, unless the responsibility is clearly passed over to other stakeholders or duty holders. However, ensuring the fire safety of a building using passive fire protection measures is the shared responsibility of everyone involved in the design, construction, compliance and management process.

Who specifies passive fire protection?

The requirements for passive fire protection can be prescribed by codes, local regulations, insurers and warranty providers. The level of performance is determined by many factors including building use, building height, fire load and occupancy type. Specifiers are normally fire engineers, designers, architects, main contractors or building owners.

Does passive fire protection in the building envelope need to be maintained?

If the products are specified and installed correctly, passive fire protection within the building’s envelope should last for the lifetime of the building without the need to be maintained. To provide additional reassurance, we have put many of our core cavity fire barrier and firestopping products through EOTA TR 024 ‘Type X’ accelerated age testing to confirm their long-term durability and service life. This is the most rigorous category available, replicating exposure to rain, UV, high temperatures, and frost and thaw cycles. This testing underpins our 60-year design life claims.

However, if the building undergoes any remediation or refurbishment works, it is important to ensure the cavity barriers, linear gap seals and firestops are not affected by this. This can be done by identifying the location of the products and ensuring they are not penetrated or moved out of their place. It is advisable to consult a fire safety engineer during the planning stages of this work.

These products should be installed precisely with no gaps, as any damage can reduce their effectiveness in slowing the progress of a fire. For more complicated renovations such as pipework, structural repairs or removing part of the building, it is advisable to have a site inspection to ensure the passive fire protection is not damaged.

How can I ensure passive fire protection is installed correctly within the building envelope?

In addition to designers, specifiers and inspectors understanding the requirements, stipulating exacting standards of workmanship and acknowledging potential site challenges, correct installation starts by ensuring onsite teams are competent, knowledgeable and skilled to prevent errors from being baked in.

This can be achieved through independent installation training initiatives with specialist training providers, third-party certification schemes and professional qualifications. We offer specialist training on the specific methods and approaches needed to install Siderise products effectively.

This includes a combination of classroom learning and practical onsite training, covering everything from ‘toolbox talks’ that ensure installation instructions and method statements are clearly understood, to dealing with tricky details and conducting benchmark installations to demonstrate compliance with the design and specification. Inspections can also be useful to verify the correct installation, whether in person by our Site Services team or via the Siderise Inspection App.

How do I know if a building has passive fire protection?

Since cavity barriers, fire stops and linear gap seals are concealed within the building envelope, it has historically been difficult to track whether a building has these installed, and if so, where. With the introduction of the ‘Golden Thread’ of information through the Building Safety Act, it is becoming standard practice to log and store all product information about a building for future reference. This is especially important for future modifications to recognise each product’s application within the building.

Siderise Site Services team can supply reports from inspection services, as well as documentation on any training and advice our technical and site services teams have been involved with. This contributes to the golden thread providing a clear digital record of exactly what’s in the building and how it was installed.

Additionally, a number of Siderise products are also produced with BSI Identify dedicated QR codes. These codes are added to products which are linked to BSI UPINs (unique persistent identification numbers) which are applied to every construction product within the BSI Identify database. When scanned, this facilitates accurate product identification, and provides rapid access to information related to specification, testing, installation, and maintenance. This feature also enables traceability throughout the building’s lifecycle.

Explore our passive fire protection product range here or get in touch with our technical team [email protected] to discuss any of your project-specific queries.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response